Project Overview

1. Chirongwa chekugadzira

600 seti / zuva (117/118 inotakura pedestral)

2. Zvinodiwa pakugadzirisa mutsara:

1) NC machining centre inokodzera otomatiki yekugadzira mutsara;

2) Hydraulic frock clamp;

3) Automatic kurodha uye blanking mudziyo uye kutakura mudziyo;

4) Yakazara yekugadzira tekinoroji uye kugadzirisa kutenderera nguva;

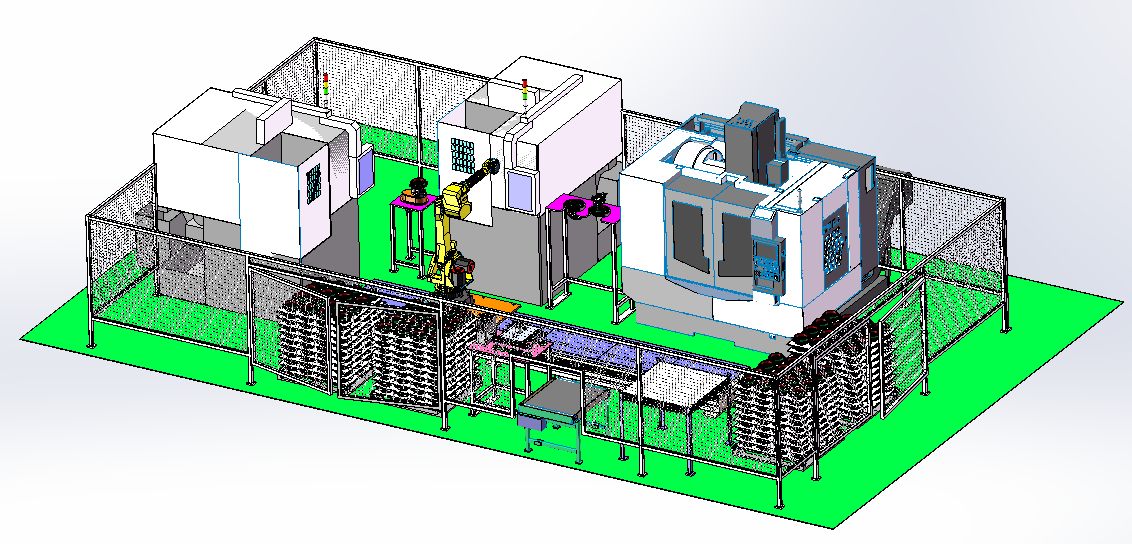

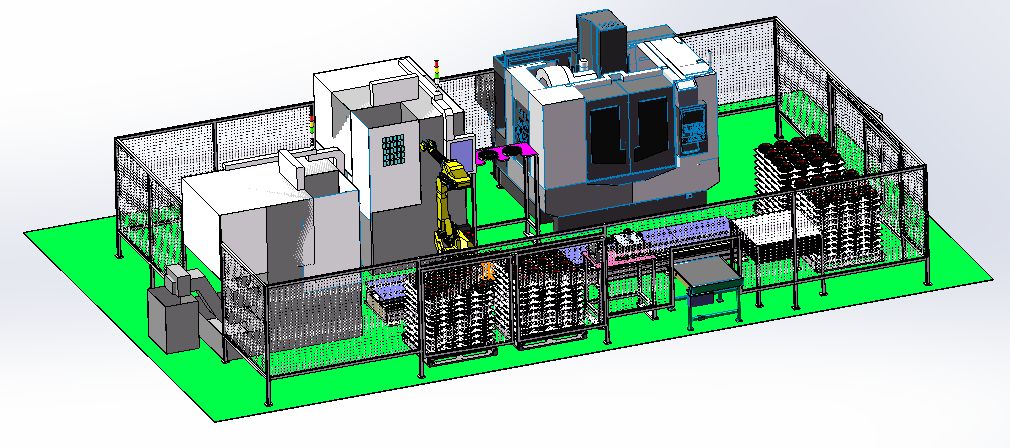

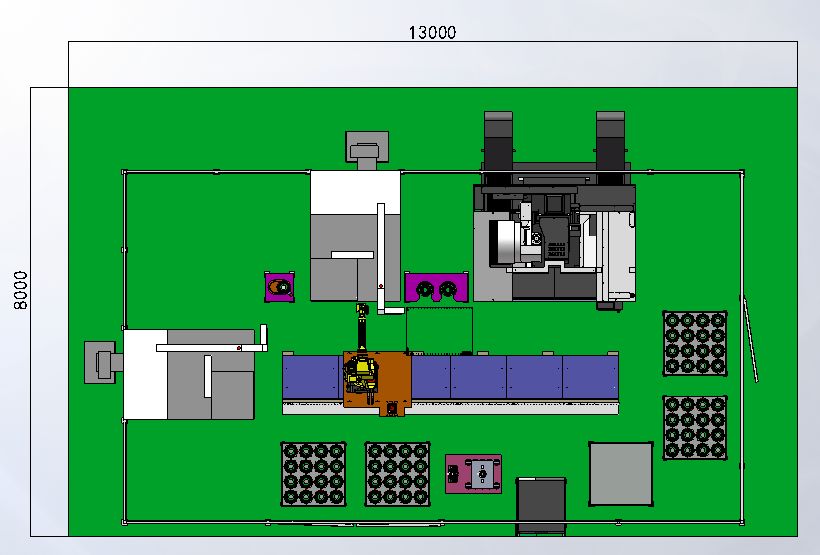

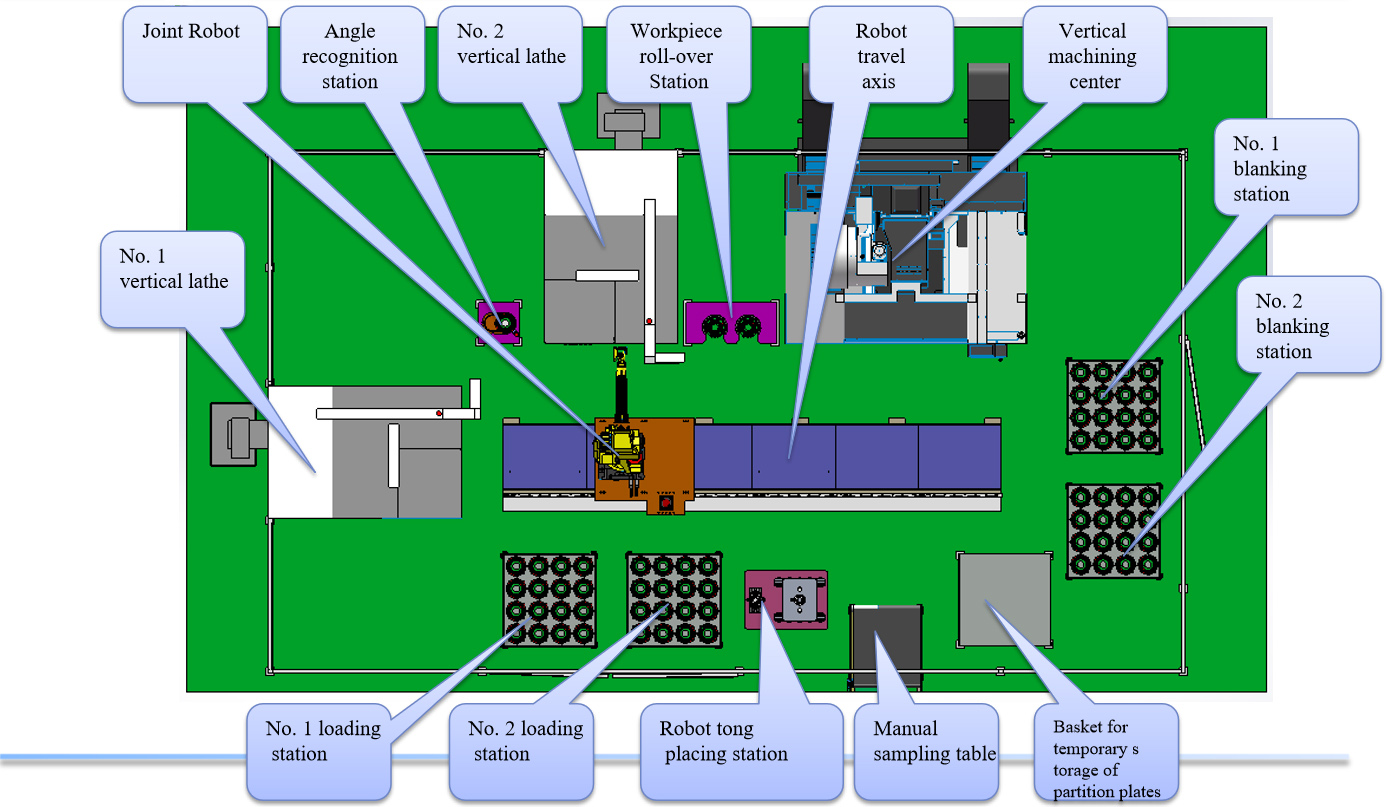

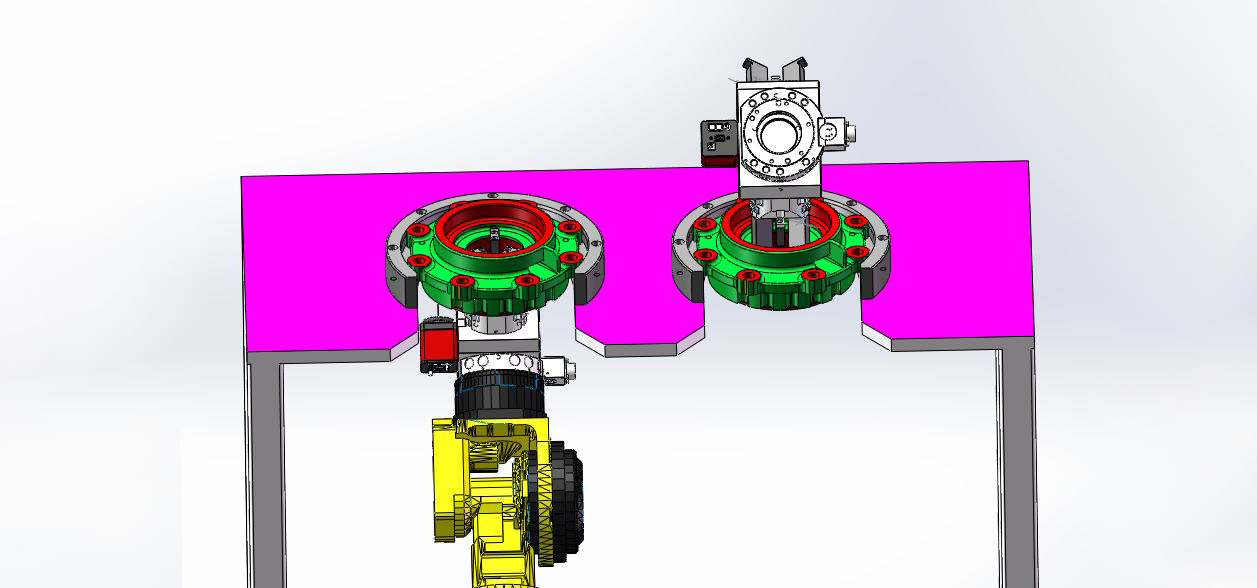

Kurongeka kweMitsetse Yekugadzira

Kurongeka kweMitsetse Yekugadzira

Nhanganyaya yeRobhoti Zviito:

1. Nemaoko isa roughly machined uye akaisa tswanda pamusoro loading table (Loading tables No. 1 and No. 2) and press the button to confirm;

2. Irobhoti inofamba ichienda kune tereyi yeNo.

3. Murairo wekutakura unotumirwa neangular recognition station. Iyo robhoti inoisa Nha. 1 chidimbu munzvimbo yekumisikidza yeturntable. Kutenderedza turntable uye tanga hurongwa hwekuzivikanwa kweangular, sarudza nzvimbo yeangular, kumisa turntable uye kupedzisa kucherechedzwa kweangular yeNhamba 1 chidimbu;

4. Nzira yekuzivikanwa kweangular inotumira murairo usina kuvhara, uye robot inotora chidimbu cheNo. Iyo turntable inotenderera uye iyo angular recognition system inotanga kumusoro kuti ione nzvimbo yeangular. Iyo turntable inomira uye kuzivikanwa kweangular yeNhamba 2 chidimbu inopedzwa, uye murairo usina kuvhara unotumirwa kunze;

5. Robhoti inogamuchira blanking command yeNo. 1 vertical lathe, inofamba ichiisa uye isina nzvimbo nzvimbo yeNo. Mushure mekuita kwapera, iyo imwe-chidimbu machining kutenderera kweiyo vertical lathe inotanga;

6. Robhoti inotora zvigadzirwa zvakapedzwa neNo. 1 vertical lathe uye inoisa panzvimbo yeNo.

7. Robhoti inogamuchira blanking command yeNo. 2 vertical lathe, inofamba kune kurodha uye nzvimbo isina kuvhara yeNo.

8. Robhoti inotora zvigadzirwa zvakapedzwa neNo. 2 vertical lathe uye inoiisa panzvimbo yeNo.

9. Robhoti inomirira murairo usina kuvharwa kubva kune vertical machining;

10. The vertical machining inotumira murairo usina kuvhara, uye robhoti inofamba ichienda kunzvimbo yekutakura uye isina kuvhara ye vertical machining, inobata uye inofambisa workpieces yeNo. 1 uye No. Iyo robhoti inoenda kune roll-over tafura kubata uye kutumira Nha. 1 uye Nha. Iyo robhoti inofamba ichibva kure nekuchengetedzwa kure kweiyo vertical machining uye inotanga imwechete yekugadzirisa kutenderera;

11. Robhoti inotamira kuNo.

Tsanangudzo:

1. Robhoti inotora 16 zvidimbu (imwe layer) pane tireyi yekurodha. Robhoti rinozotsiva kapu yekukweva tong uye roisa ndiro yekuparadzanisa mubhasikiti rekuchengetera chinguva;

2. Robhoti inotakura 16 zvidimbu (imwe layer) pane blanking tray. Robhoti rinofanira kutsiva kapu yekusveta tong kamwe chete, uye kuisa ndiro yekuparadzanisa pamusoro pechikamu chezvikamu kubva mubhasikiti rekuchengetedza kwenguva pfupi;

3. Maererano nehuwandu hwekuongorora, iva nechokwadi chokuti robhoti inoisa chikamu pane tafura yekuenzanisa sampling;

| 1 | Iyo machining cycle timetable | ||||||||||||||

| 2 | Mutengi | Workpiece zvinhu | QT450-10-GB/T1348 | Muenzaniso wemuchina chishandiso | Archive Nha. | ||||||||||

| 3 | Product Name | 117 Kutakura chigaro | Dhirowa Nha. | DZ90129320117 | Zuva rekugadzirira | 2020.01.04 | Yakagadzirirwa na | ||||||||

| 4 | Process step | Banga Nha. | machining content | Zita reChishandiso | Kucheka Diameter | Cutting speed | Kutenderera kumhanya | Feed per revolution | Kudyisa nemuchina mudziyo | Nhamba yekucheka | Nzira imwe neimwe | Machining nguva | Idle Time | Ina-axis inotenderera nguva | Tool kuchinja nguva |

| 5 | Aihwa. | Aihwa. | Desorptions | Zvishandiso | D mm | n | R pm | mm/Rev | mm/Min | Nguva | mm | Sec | Sec | Sec | |

| 6 |  | ||||||||||||||

| 7 | 1 | T01 | Milling mounting gole pamusoro | Diameter ye40-face milling cutter | 40.00 | 180 | 1433 | 1.00 | 1433 | 8 | 40.0 | 13.40 | 8 | 4 | |

| 8 | Dhobora DIA 17 maburi anokwira | DIA 17 COMBINED DILL | 17.00 | 100 | 1873 | 0.25 | 468 | 8 | 32.0 | 32.80 | 8 | 4 | |||

| 9 | T03 | DIA 17 buri kumashure chamfering | Reverse chamfering cutter | 16.00 | 150 | 2986 | 0.30 | 896 | 8 | 30.0 | 16.08 | 16 | 4 | ||

| 10 | Tsanangudzo: | Nguva yekucheka: | 62 | Chepiri | Inguva yekurovera nekugadzirisa uye yekurodha uye kuvharika zvinhu: | 30.00 | Chepiri | ||||||||

| 11 | Nguva yekubatsira: | 44 | Chepiri | Yese machining man-maawa: | 136.27 | Chepiri | |||||||||

| 1 | Iyo machining cycle timetable | |||||||||||||||||

| 2 | Mutengi | Workpiece zvinhu | QT450-10-GB/T1348 | Muenzaniso wemuchina chishandiso | Archive Nha. | |||||||||||||

| 3 | Product Name | 118 Kutakura chigaro | Dhirowa Nha. | DZ90129320118 | Zuva rekugadzirira | 2020.01.04 | Yakagadzirirwa na | |||||||||||

| 4 | Process step | Banga Nha. | machining content | Zita reChishandiso | Kucheka Diameter | Cutting speed | Kutenderera kumhanya | Feed per revolution | kudya nemuchina mudziyo | Nhamba yekucheka | Nzira imwe neimwe | Machining nguva | Idle Time | Ina-axis inotenderera nguva | Tool kuchinja nguva | |||

| 5 | Aihwa. | Aihwa. | Desorptions | Zvishandiso | D mm | n | R pm | mm/Rev | mm/Min | Nguva | mm | Sec | Sec | Sec | ||||

| 6 |

| |||||||||||||||||

| 7 | 1 | T01 | Milling mounting gole pamusoro | Diameter ye40-face milling cutter | 40.00 | 180 | 1433 | 1.00 | 1433 | 8 | 40.0 | 13.40 | 8 | 4 | ||||

| 8 | T02 | Dhobora DIA 17 maburi anokwira | DIA 17 COMBINED DILL | 17.00 | 100 | 1873 | 0.25 | 468 | 8 | 32.0 | 32.80 | 8 | 4 | |||||

| 9 | T03 | DIA 17 buri kumashure chamfering | Reverse chamfering cutter | 16.00 | 150 | 2986 | 0.30 | 896 | 8 | 30.0 | 16.08 | 16 | 4 | |||||

| 10 | Tsanangudzo: | Nguva yekucheka: | 62 | Chepiri | Inguva yekurovera nekugadzirisa uye yekurodha uye kuvharika zvinhu: | 30.00 | Chepiri | |||||||||||

| 11 | Nguva yekubatsira: | 44 | Chepiri | Yese machining man-maawa: | 136.27 | Chepiri | ||||||||||||

| 12 | ||||||||||||||||||

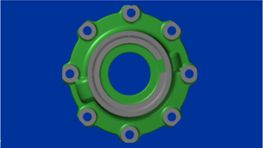

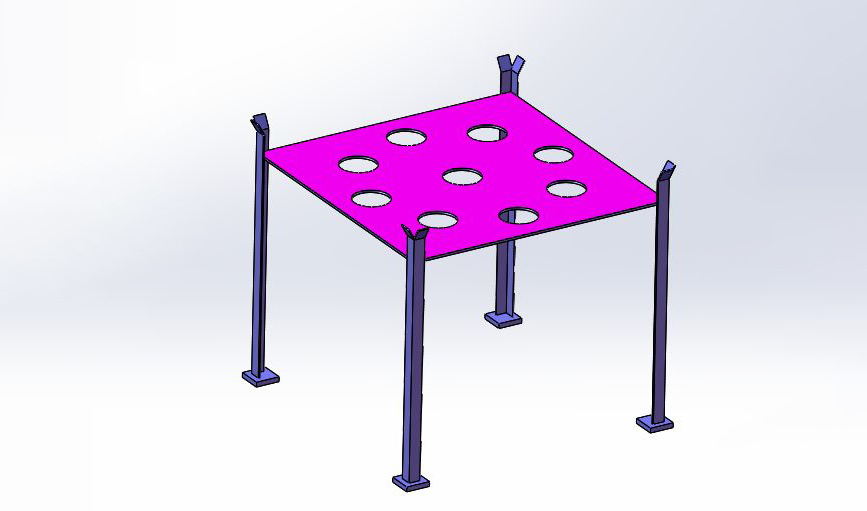

Nzvimbo yekuvhara yemutsara wekugadzira

Nhanganyaya yezvikamu zvikuru zvinoshanda zvekugadzira mutsara

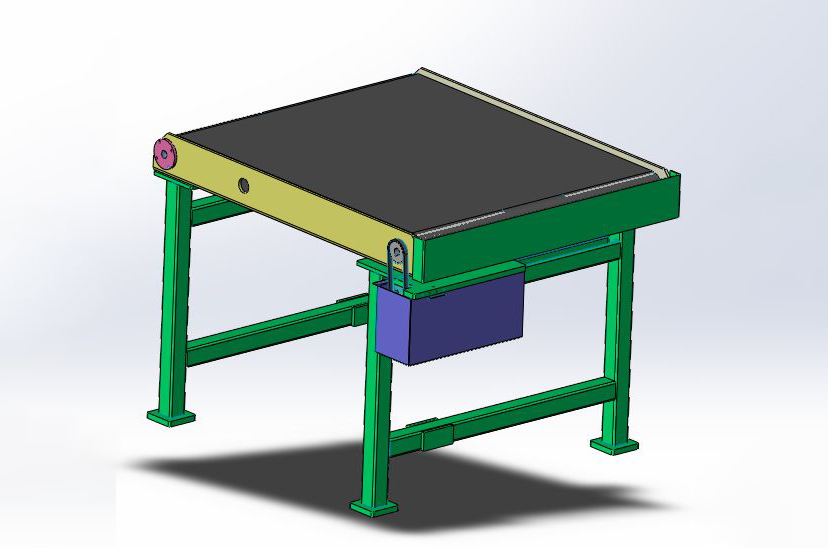

Nhanganyaya yekurodha uye blanking system

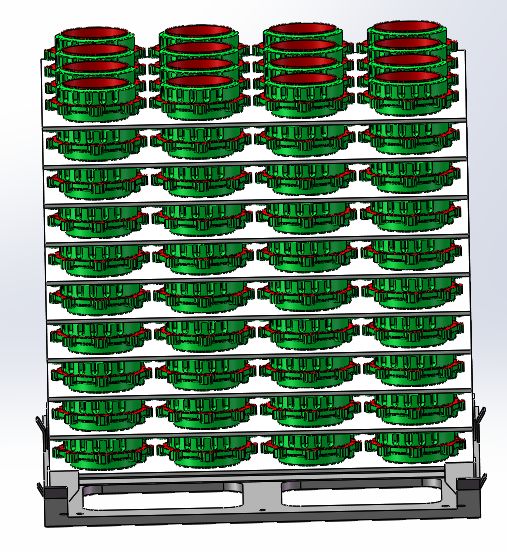

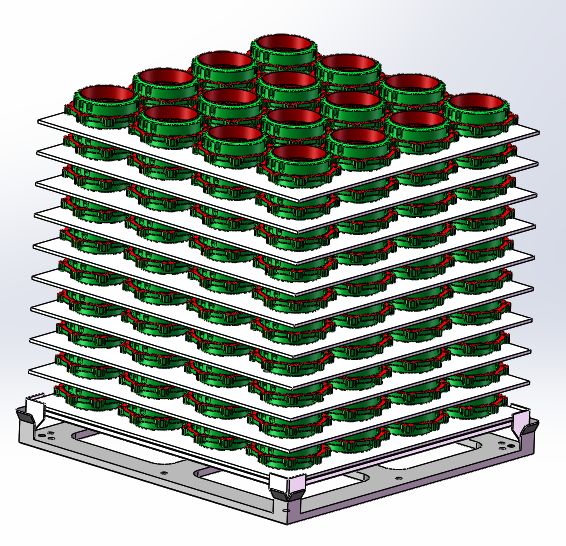

Midziyo yekuchengetera yeotomatiki yekugadzira mutsara muchirongwa ichi ndeiyi: Iyo tireyi yakaturikidzana (huwandu hwezvimedu zvichaiswa patireyi yega yega zvichataurirana nemutengi), uye kuiswa kweiyo workpiece mutireyi kuchatemwa mushure mekupa 3D kudhirowa kweworkpiece isina chinhu kana chinhu chaicho.

1. Vashandi vanorongedza zvikamu zvinenge zvakagadziriswa patireyi yezvinhu (sezvinoratidzwa mumufananidzo) uye vanozviisa kune forklift panzvimbo yakatarwa;

2. Mushure mekutsiva tireyi yeforklift, nemaoko tinya bhatani kuti usimbise;

3. Robhoti inobata workpiece kuti iite basa rekurodha;

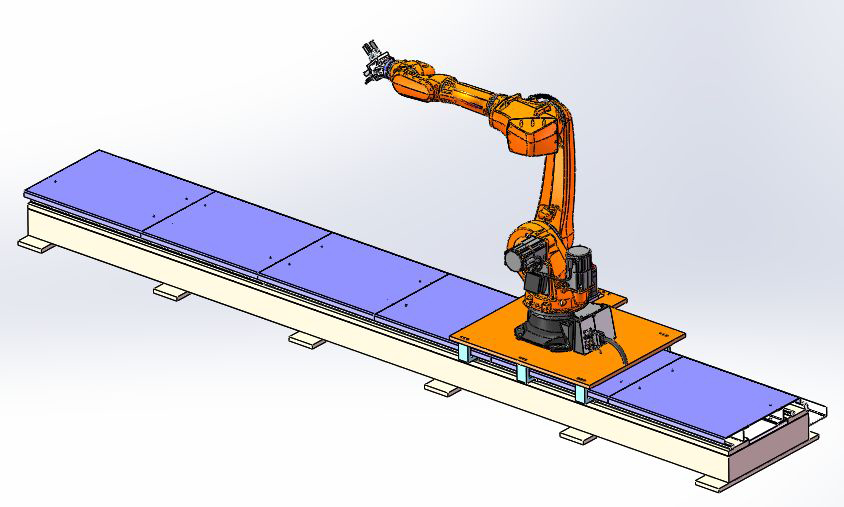

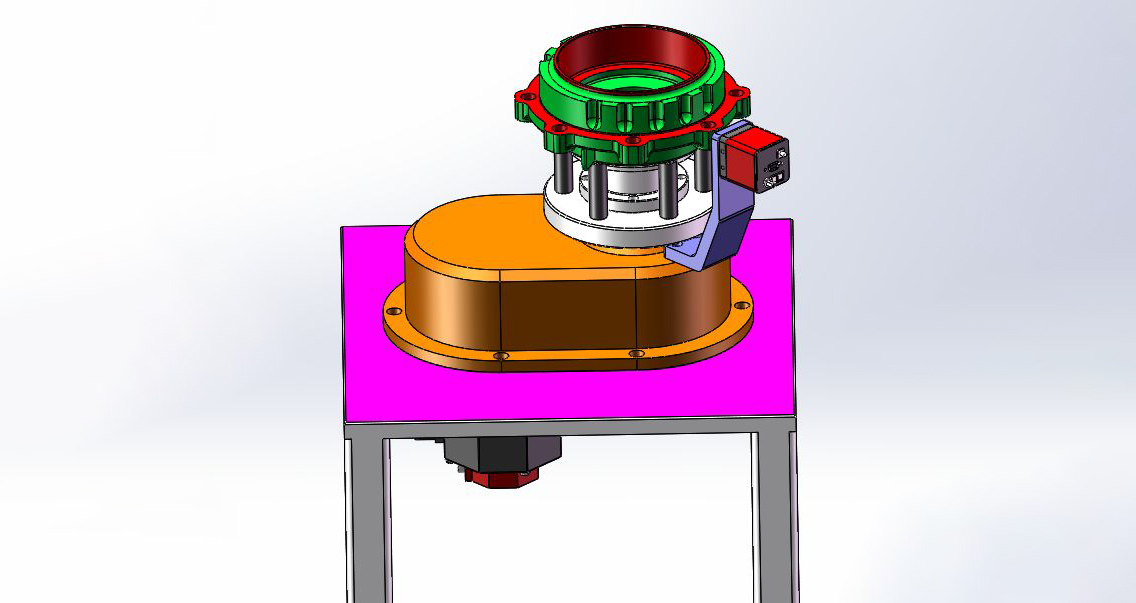

Nhanganyaya yeRobot Travel Axis

Chimiro chacho chinoumbwa nerobhoti rakabatana, servo motor drive uye pinion uye rack drive, kuitira kuti robhoti iite rectilinear kufamba nekudzoka. Iyo inoziva basa rerobhoti rimwe rinoshandisa akawanda maturusi emuchina uye inobata workpiece pazviteshi zvakati wandei uye inogona kuwedzera kuvharika kwekushanda kwemarobhoti akabatana;

Kufamba track inoshandisa base yakashomerwa nemapombi esimbi uye inofambiswa ne servo mota, pinion uye rack drive, kuwedzera kuvharika kwekushanda kwerobhoti yakabatana uye nekunatsiridza mwero wekushandiswa kwerobhoti; Nzira yekufambisa inoiswa pasi;

Chenxuan robhoti:SDCX-RB500

| Basic data | |

| Type | SDCX-RB500 |

| Nhamba yemasanhu | 6 |

| Maximum coverage | 2101mm |

| Pose repeatability (ISO 9283) | ± 0.05mm |

| Kurema | 553kg |

| Kudzivirirwa kupatsanurwa kwerobhoti | Chiyero chekudzivirira, IP65 / IP67in-line wrist(IEC 60529) |

| Mounting chinzvimbo | Sirin'i, kona inotenderwa yekurerekera ≤ 0º |

| Kupera kwepamusoro, pendi | Base furemu: dema (RAL 9005) |

| Ambient tembiricha | |

| Operation | 283 K kusvika 328 K (0 °C kusvika +55 °C) |

| Kuchengeta uye chekufambisa | 233 K kusvika 333 K (-40 °C kusvika +60 °C) |

Iine huwandu hwakawanda hwekufamba domain kuseri uye kuzasi kwerobhoti, kuve iyo modhi inokwanisa kukwidziridzwa nekusimudza sirin'i. Nekuti iyo lateral upamhi hwerobhoti yakaderedzwa kusvika painogumira, zvinokwanisika kuisirwa padhuze kune iri padyo robhoti, clamp, kana workpiece. High-speed kufamba kubva panzvimbo yekumira kuenda panzvimbo yekushanda uye nekukasira kuisa panguva yekufamba-famba kwechinhambwe.

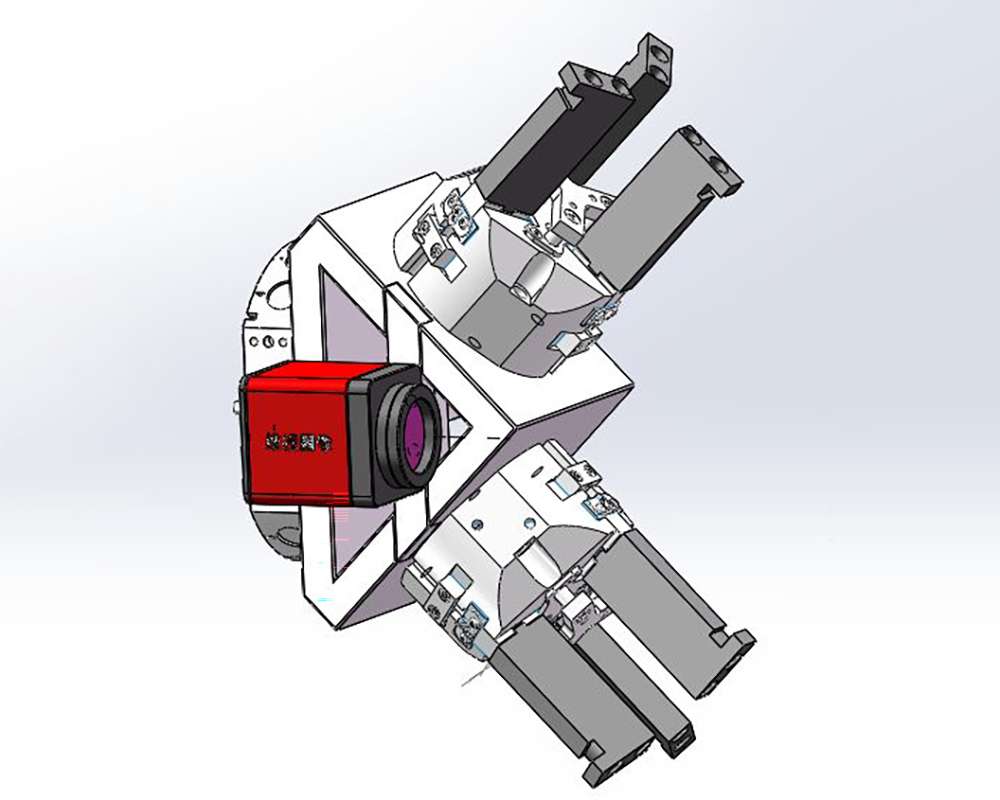

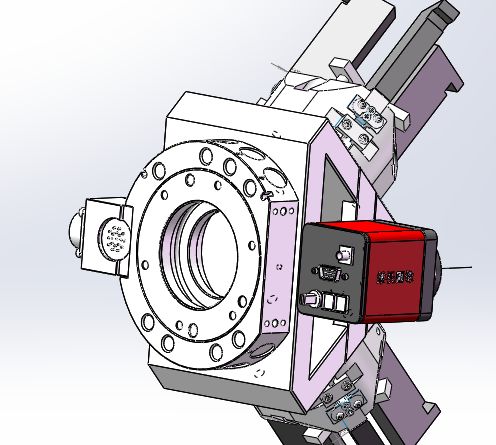

Hungwaru robhoti kurodha uye blanking tong michina

Robot partition plate tong mechanism

Tsanangudzo:

1. Tichifunga nezve maficha echikamu ichi, isu tinoshandisa matatu-claw yekunze inotsigira nzira yekuisa uye isina chinhu zvinhu, izvo zvinogona kuona nekukurumidza kutendeuka kwezvikamu zvemuchina chishandiso;

2. Iyo dhizaini inoshongedzerwa neiyo nzvimbo yekuona sensor uye yekumanikidza sensor kuti ione kana iyo clamping mamiriro uye kumanikidza kwezvikamu zvakajairika;

3. Iyo michina inoshongedzerwa nepressurizer, uye workpiece haizoputsike munguva pfupi kana kukanganisa kwesimba uye gasi kubviswa kwemhepo huru yedunhu;

4. Ruoko rwekushandura mudziyo unogamuchirwa. Changing tong mechanism inogona kukurumidza kupedzisa kusungirirwa kwezvinhu zvakasiyana.

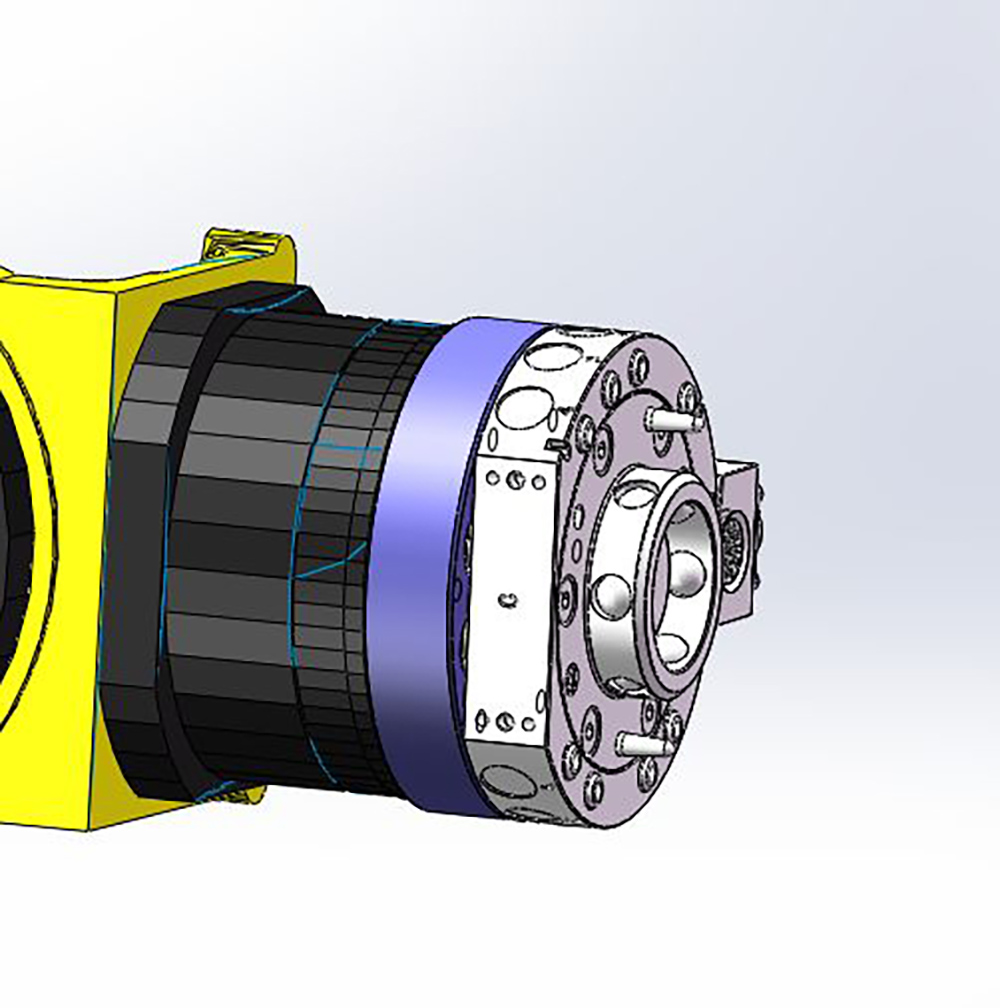

Nhanganyaya yeTong Changing Device

Chaiyo tong inoshandura mudziyo unoshandiswa kukurumidza kushandura marobhoti tong, maturusi ekupedzisira, uye mamwe ma actuators. Deredza nguva yekugadzira isina basa uye wedzera robhoti kuchinjika, inoratidzwa se:

1. Vhura uye simbisa kudzvanywa kwemhepo;

2. Simba rakasiyana-siyana, mvura uye gasi modules inogona kushandiswa;

3. Standard configuration inogona kukurumidza kubatana nemhepo inobva;

4. Masangano einishuwarenzi akakosha anogona kudzivirira njodzi yekudzima gasi netsaona;

5. Hapana chitubu chekuita simba; 6. Inoshanda kune otomatiki munda;

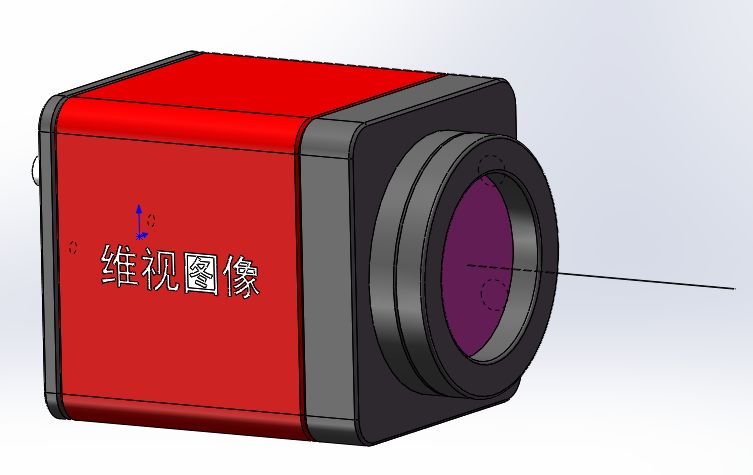

Nhanganyaya yeVision System-Industrial Kamera

1. Iyo kamera inotora yakakwirira-yepamusoro CCD uye CMDS chips, iyo ine maitiro epamusoro-soro reshiyo, kunzwisiswa kwepamusoro, kukwirira kwechiratidzo-kusvika-frequency ratio, yakafara dhizaini, yakanakisa yekufungidzira mhando uye yekutanga-kirasi kirasi yekudzorera ruvara;

2. Nzvimbo yekamera kamera ine nzira mbiri dzekutumira data: GIGabit Ethernet (GigE) interface uye USB3.0 interface;

3. Iyo kamera ine compact structure, kutaridzika kuduku, kureruka uye kuiswa. High transmission speed, simba rinopesana nekupindira, simba rakagadzikana remufananidzo wepamusoro-soro; Inoshandiswa pakuverenga kodhi, kuona kukanganisa, DCR uye kuzivikanwa kwemaitiro; Kamera yeruvara ine simba rakasimba rekudzoreredza kwemavara, inokodzera mamiriro ane yakakwira kucherechedzwa kwemavara zvinodiwa;

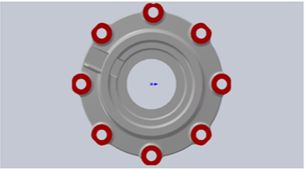

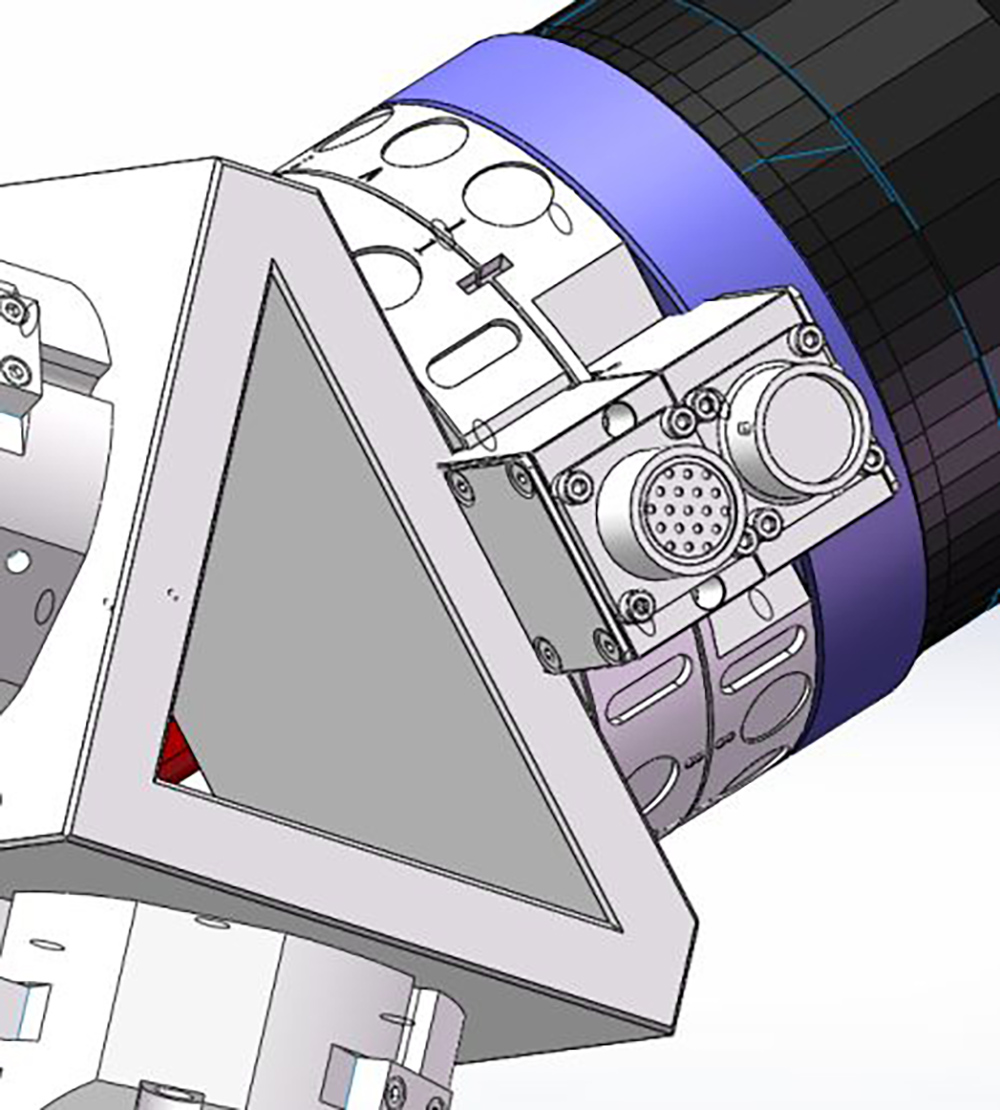

Nhanganyaya yeAngular Automatic Recognition System

Basa Nhanganyaya

1. Iyo robhoti inosungirira iyo workpieces kubva pakutakura mabhasikiti uye inoatumira kunzvimbo yekumisikidza yeturntable;

2. Turntable inotenderera pasi pekutyaira kwe servo motor;

3. Maonero ekuona (industrial camera) anoshanda kuti aone nzvimbo yeangular, uye turntable inomira kuti ione nzvimbo inodiwa yeangular;

4. Robhoti inotora workpiece uye inoisa chimwe chidimbu mukati kuti chizivikanwe cheangular;

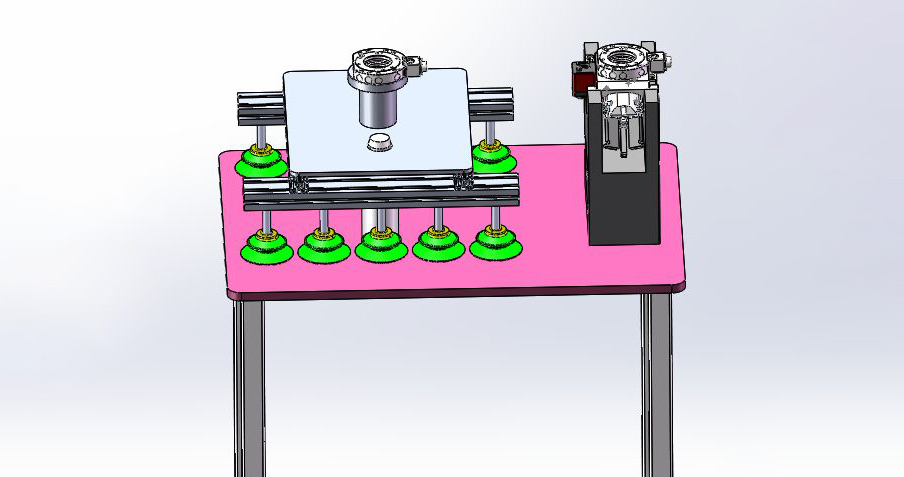

Nhanganyaya kune Workpiece Roll-over Tafura

Roll-over station:

1. Robhoti inotora workpiece uye inoiisa panzvimbo yekuisa panzvimbo patafura-pamusoro petafura (kuruboshwe chiteshi mumufananidzo);

2. Robhoti inobata workpiece kubva kumusoro kuti ione rollover ye workpiece;

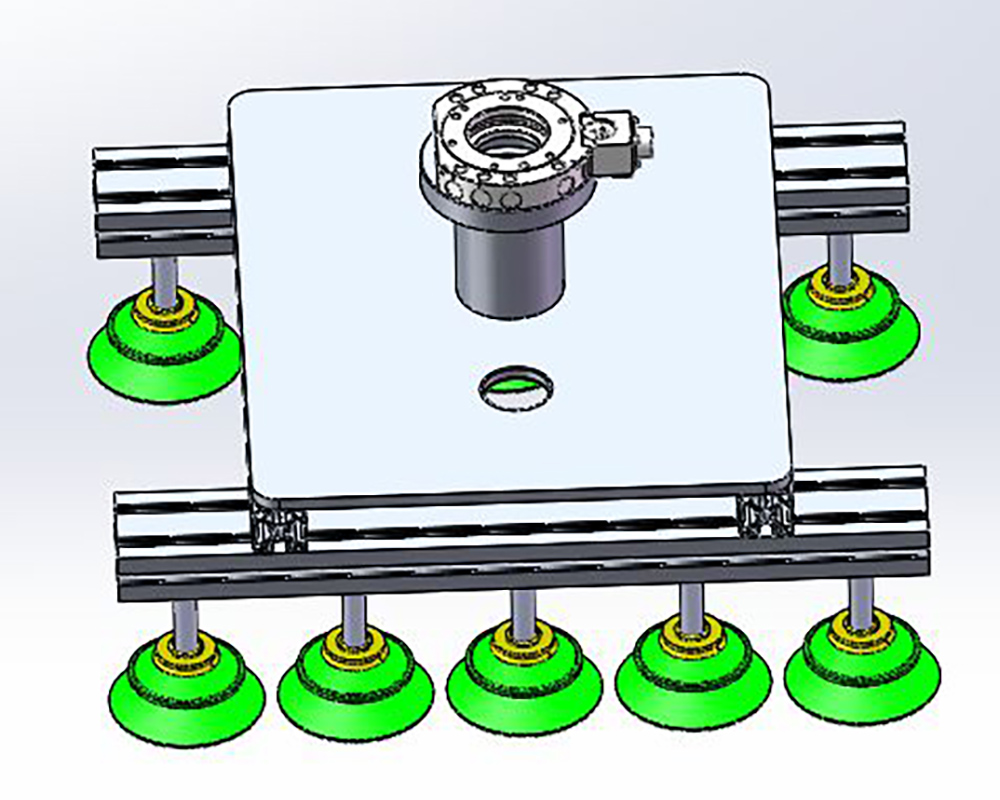

Robhoti tong kuisa tafura

Basa Nhanganyaya

1. Mushure mechikamu chimwe nechimwe chezvikamu zvakatakurwa, chidimbu chekuparadzanisa chigadziro chichaiswa mubhasikiti rekuchengetedza kwenguva pfupi kune mahwendefa ekuparadzanisa;

2. Robhoti rinogona kukurumidza kutsiviwa nekapu yekusveta tong netong inoshandura mudziyo uye kubvisa mahwendefa ekuparadzanisa;

3. Mushure mekunge mahwendefa ekuparadzanisa aiswa zvakanaka, bvisa kapu yekukwevera tong uye shandura nepeneumatic tong kuti uenderere mberi nekutakura uye kuvhara zvinhu;

Tswanda yekuchengetera kwenguva pfupi mahwendefa ekuparadzanisa

Basa Nhanganyaya

1. Tswanda yenguva pfupi yemarata ekuparadzanisa inogadzirwa nekurongwa sezvo mahwendefa ekuparadzanisa anotakurwa anotanga kubviswa uye mahwendefa ekuparadzanisa anozoshandiswa gare gare;

2. Mahwendefa ekurongedzerwa anoiswa nemaoko uye ari mukusagadzikana. Mushure mokunge ndiro yekuparadzanisa yaiswa mubhasiki rekuchengetedza kwenguva pfupi, robot inogona kutora uye kuiisa zvakanaka;

Manual sampling table

Tsanangudzo:

1. Seta manyorerwo akasiyana-siyana ekuenzanisa sampling frequency yezvikamu zvakasiyana zvekugadzira, izvo zvinogona kunyatso tarisa kushanda kweyero yepamhepo;

2. Mirayiridzo Yekushandisa: Iyo manipulator ichaisa iyo workpiece kunzvimbo yakagadziriswa patafura yekuenzanisira maererano nefrequency yakatarwa nemaoko, uye nekukurumidza nechiedza chitsvuku. Muongorori achadzvanya bhatani kuti atakure workpiece kunzvimbo yakachengeteka kunze kwekuchengetedzwa, tora workpiece yekuyera uye uichengete zvakasiyana mushure mekuyera;

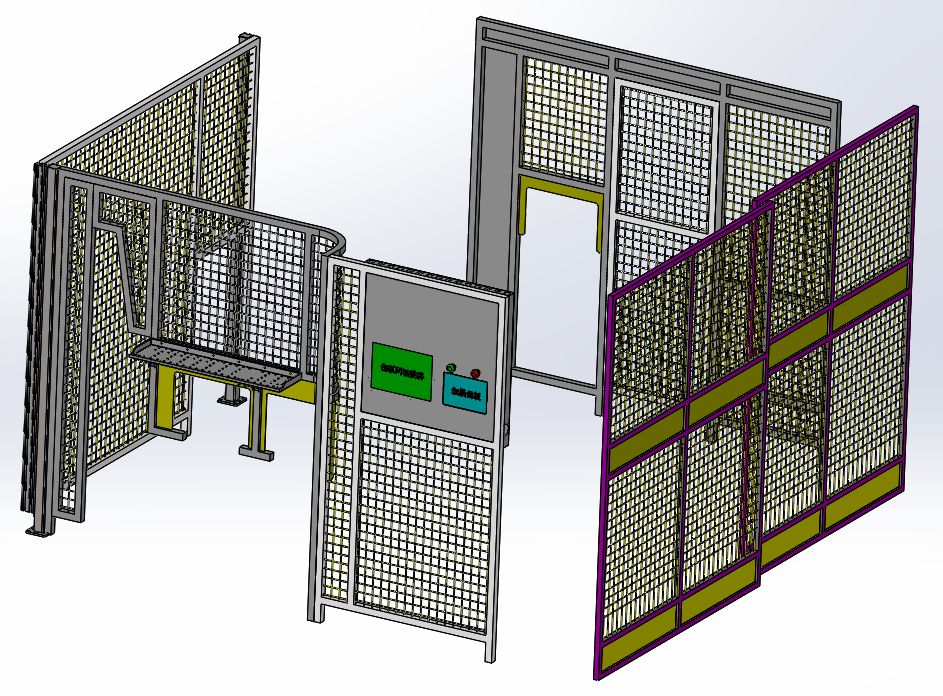

Zviviriro zvinodzivirira

Iyo inoumbwa neakareruka aluminium mbiri (40 × 40) + mesh (50 × 50), uye iyo yekubata skrini uye yekumisa bhatani bhatani rinogona kubatanidzwa pane zvinodzivirira, kubatanidza kuchengetedza uye aesthetics.

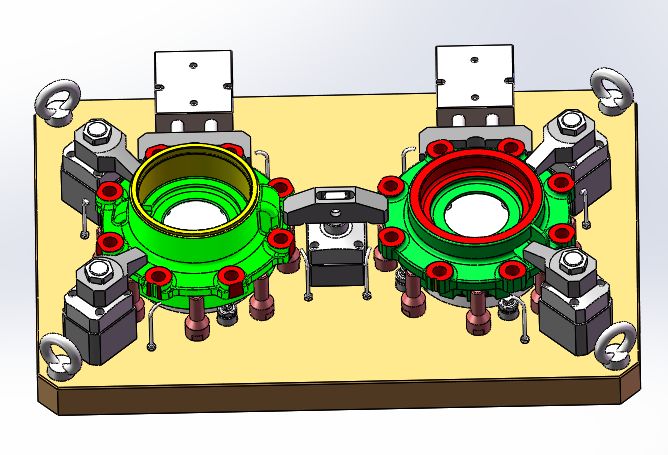

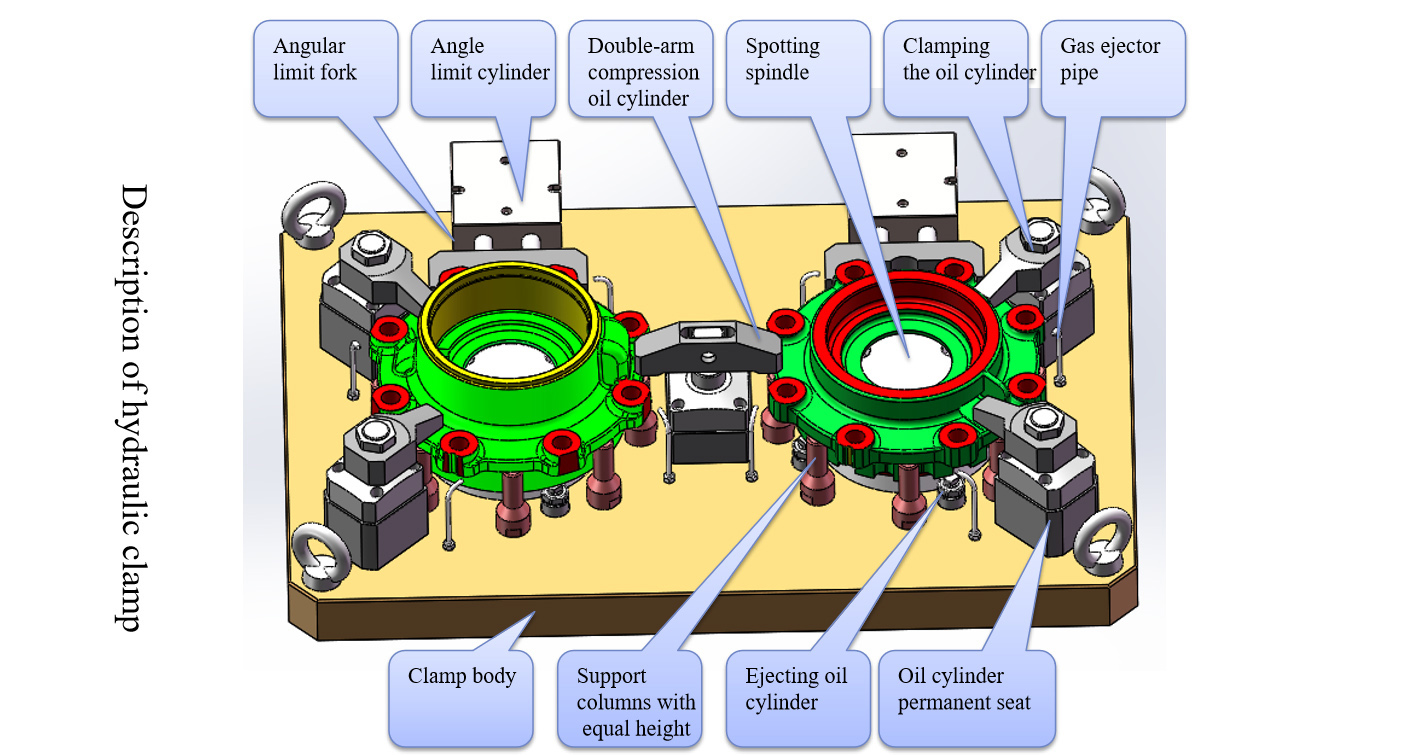

Kutanga kweOP20 Hydraulic Fixture

Mirayiridzo Yekugadzirisa:

1. Tora φ165 bhomba remukati segomba rekutanga, tora D datum sendege yepasi, uye tora arc yekunze yemukuru wemakomba maviri anokwirisa semuganhu weakona;

2. Dzora kusunungura uye kudzvanya chiito chendiro yekutsikirira nekuraira kwemuchina chishandiso M kupedzisa chamfering kugadziridzwa kwepamusoro ndege yekukwirisa gomba boss, 8-φ17 gomba rinokwira uye migumo yese yegomba;

3. Iyo gadziriso ine mabasa ekuisa, otomatiki clamping, kuona mhepo yakamanikana, otomatiki kusunungura, otomatiki ejection, otomatiki chip flushing uye otomatiki kuchenesa yekumisikidza datum ndege;

Equipment Zvinodiwa zveKugadzira Line

1. Iyo yekugadzira tambo yemidziyo yesimbi ine mabasa e otomatiki clamping uye kusunungura, uye inoona otomatiki clamping uye kusunungura mabasa pasi pekutonga kwemasaini eiyo manipulator system kushandira pamwe nekurodha uye kuvharika chiito;

2. Iyo skylight chinzvimbo kana otomatiki gonhi module ichachengeterwa simbi ndiro yekugadzira mutsara michina, kurongeka nemagetsi ekudzora chiratidzo uye manipulator kutaurirana kwekambani yedu;

3. Michina yekugadzira mutsara ine kutaurirana nemugadziri kuburikidza nekubatanidza nzira ye-heavy-load connector (kana aviation plug);

4. Michina yekugadzira mutsara ine mukati (kupindira) nzvimbo yakakura kudarika yakachengeteka yehutano hwemanipulator jaw action;

5. Michina yekugadzira mitsara ichave nechokwadi chekuti hapana chakasara chesimbi machipisi panzvimbo yekumisikidza yembambo. Kana zvichidikanwa, kuvhuvhuta kwemhepo kuchawedzerwa pakuchenesa (iyo chuck ichatenderera pakuchenesa);

6. Iyo yekugadzira mutsara michina ine yakanaka chip breaking. Kana zvichidikanwa, iyo yekubatsira yakakwirira-kudzvanya chip yekutyora mudziyo wekambani yedu ichawedzerwa;

7. Kana michina yekugadzira mutsara ichida kumira kwakaringana kwemuchina wekushandisa spindle, wedzera basa iri uye upe inoenderana masaini emagetsi;

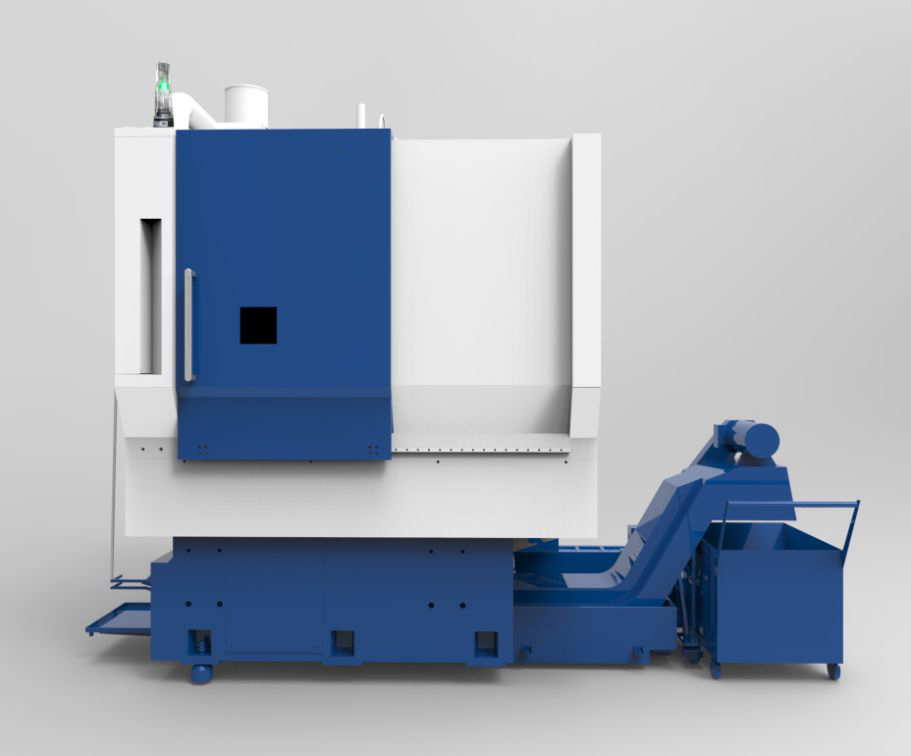

Kusuma Vertical Lathe VTC-W9035

VTC-W9035 NC vertical lathe inokodzera machining anotenderera zvikamu senge giya blanks, flanges uye akasarudzika-mabhomba, kunyanya akakodzera kune chaiyo, kuchengetedza-basa uye nekunyatso shandura zvikamu zvakaita sedhisiki, hubs, mabhureki disc, miviri yepombi, miviri yevharuvhu uye mabhomba. Chishandiso chemuchina chine zvakanakira kunaka kwese kuomarara, kurongeka kwepamusoro, chiyero chakakura chekubvisa simbi pane imwe nguva yeyuniti, kuchengetedzwa kwakanaka kwekuchengetedza, kuvimbika kwepamusoro, kugadzirisa kuri nyore, nezvimwe uye zvakasiyana-siyana zvekushandisa. Kugadzirwa kwemutsara, kushanda kwepamusoro uye kudhura kwakaderera.

| Muenzaniso mhando | VTC-W9035 |

| Maximum turning diameter yemubhedha wemuviri | Φ900 mm |

| Maximum turning diameter pane inotsvedza ndiro | Φ590 mm |

| Maximum kutendeuka dhayamita yeworkpiece | Φ850 mm |

| Maximum kutendeuka kureba kweworkpiece | 700 mm |

| Speed range ye spindle | 20-900 r/min |

| System | FANUC 0i - TF |

| Kunyanya kurova kweX/Z axis | 600/800 mm |

| Inokurumidza kufamba kumhanya yeX/Z axis | 20/20 m/min |

| Kureba, upamhi uye urefu hwemuchina chishandiso | 3550*2200*3950 mm |

| Projects | Unit | Parameter | |

| Processing range | X axis kufamba | mm | 1100 |

| X axis kufamba | mm | 610 | |

| X axis kufamba | mm | 610 | |

| Kureba kubva pamhino yekuruka kuenda kubhenji rekushanda | mm | 150–760 | |

| Workbench | Saizi yeworkbench | mm | 1200 × 600 |

| Maximum load ye workbench | kg | 1000 | |

| T-groove (saizi × uwandu × nzvimbo) | mm | 18×5×100 | |

| Kudyisa | Kukurumidza kudyisa kumhanya kweX/Y/Z axis | m/min | 36/36/24 |

| Spindle | Kutyaira mode | Bhandi rudzi | |

| Spindle taper | BT40 | ||

| Maximum yekushandisa kumhanya | r/min | 8000 | |

| Simba (Rakatemerwa/Ukuru) | KW | 11/18.5 | |

| Torque (Yakayerwa/Yakanyanya) | N·m | 52.5/118 | |

| Kururama | X/Y/Z axis positioning kurongeka (hafu yakavharwa loop) | mm | 0.008 (hurefu hwose) |

| X/Y/Z axis kudzokorora kurongeka (hafu yakavharwa loop) | mm | 0.005 (hurefu hwose) | |

| Tool magazine | Type | Disc | |

| Tool magazini kukwanisa | 24 | ||

| Maximum tool size(Chishandiso chizere dhayamita / chisina chinhu chiri padyo nedhayamita / kureba) | mm | Φ78/Φ150/ 300 | |

| Maximum tool uremu | kg | 8 | |

| Miscellaneous | Air supply pressure | MPa | 0.65 |

| Simba rakawanda | KVA | 25 | |

| Yakazara dimension yemuchina chishandiso (kureba × upamhi × kureba) | mm | 2900×2800×3200 | |

| Huremu hwemuchina chishandiso | kg | 7000 | |