Maitiro Ongororo yeKugadzira Line

Die retrorei im technischen prozess

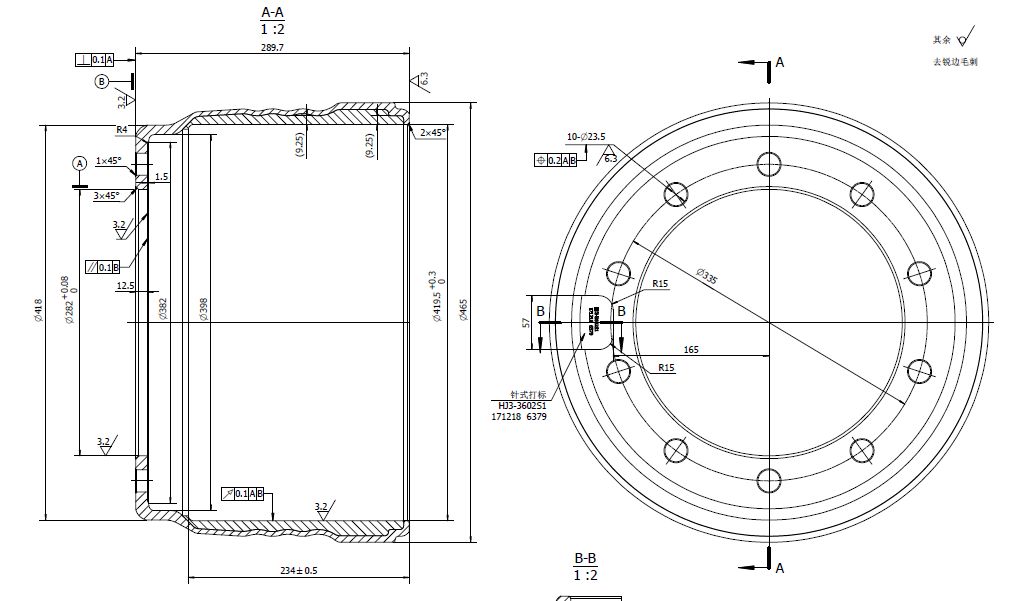

1. Iyo inoraswa clamping process inogamuchirwa panguva yekutendeuka. Kushandura zvese machining zvikamu, kusanganisira pasi pepamusoro pezvishandiso.

2. Panguva yekuchera, hydraulic clamps ichashandiswa kutsvaga nehupamhi hwemukati hwe Φ282 uye chiso chepamusoro chepamusoro, dhiraivha 10-Φ23.5 gomba rinokwira uye chamfering kumativi ose maviri, uye kugaya nzvimbo yepneumatic marking;

Equipment List

| OP10 machining Cycle timer | |||||||||||||||

| Tsanangudzo Yenzira |

| ||||||||||||||

| Mutengi | Workpiece zvinhu | 45 | Muenzaniso wemuchina chishandiso | Archive Nha. | |||||||||||

| Product Name | Kucheka mudziyo shaft welded zvikamu | Dhirowa Nha. | Zuva rekugadzirira | 2021.1.19 | Yakagadzirirwa na | ||||||||||

| Process step | Banga Nha. | machining content | Zita reChishandiso | Kucheka Diameter | Cutting speed | Kutenderera kumhanya | Feed per revolution | kudya nemuchina mudziyo | Nhamba yekucheka | Nzira imwe neimwe | Machining nguva | Idle Time | Simbisa uye sunungura | Tool kuchinja nguva | |

| Aihwa. | Aihwa. | Desorptions | Zvishandiso | D mm | VcM/min | R pm | mm/Rev | mm/Min | Nguva | Kureba mm | Sec | Sec | Sec | ||

| 1 | T01 | Isa kumucheto kwepamusoro kumeso | 455.00 | 450 | 315 | 0.35 | 110 | 1 | 20.0 | 10.89 | 3 | 3 | |||

| 2 | T02 | Lathe inosvika DIA 419.5 yemukati bore, DIA 382 nhanho kumeso uye DIA 282 yemukati bore | 419.00 | 450 | 342 | 0.35 | 120 | 1 | 300.0 | 150.36 | 3 | 3 | |||

| 3 | T03 | Lathe iyo yekupedzisira kumeso chaiko | 455.00 | 450 | 315 | 0.25 | 79 | 1 | 20.0 | 15.24 | 3 | ||||

| 4 | T04 | Lathe chaizvo iyo DIA 419.5 yemukati bore, DIA 382 nhanho kumeso uye DIA 282 yemukati bore | 369.00 | 450 | 388 | 0.25 | 97 | 1 | 300. 0 | 185.39 | |||||

| 5 | T05 | Lathe reversely uye zvakangoita yepasi yekupedzisira kumeso | 390.00 | 420 | 343 | 0.35 | 120 | 1 | 65.0 | 32.49 | 3 | ||||

| 6 | T06 | Lathe reversely uye chaizvo iyo yakaderera yekupedzisira kumeso | 390.00 | 450 | 367 | 0.25 | 92 | 1 | 65.0 | 42.45 | 3 | ||||

| Tsanangudzo: | Nguva yekucheka: | 437 | Chepiri | Inguva yekurovera nekugadzirisa uye yekurodha uye kuvharika zvinhu: | 15.00 | Chepiri | |||||||||

| Nguva yekubatsira: | 21 | Chepiri | Yese machining man-maawa: | 472.81 | Chepiri | ||||||||||

| OP20 machining Cycle timer | |||||||||||||||

| Tsanangudzo Yenzira |  | ||||||||||||||

| Mutengi | Workpiece zvinhu | HT250 | Muenzaniso wemuchina chishandiso | Archive Nha. | |||||||||||

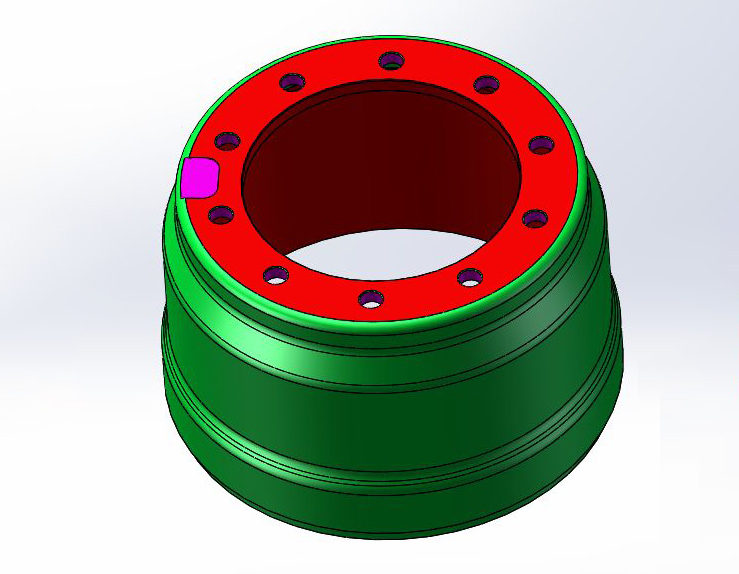

| Product Name | Brake drum | Dhirowa Nha. | Zuva rekugadzirira | 2021.1.19 | Yakagadzirirwa na | ||||||||||

| Process step | Banga Nha. | machining content | Zita reChishandiso | Kucheka Diameter | Cutting speed | Kutenderera kumhanya | Feed per revolution | kudya nemuchina mudziyo | Nhamba yekucheka | Nzira imwe neimwe | Machining nguva | Idle Time | Simbisa uye sunungura | Tool kuchinja nguva | |

| Aihwa. | Aihwa. | Desorptions | Zvishandiso | D mm | VcM/min | R pm | mm/Rev | mm/Min | Nguva | Kureba mm | Sec | Sec | Sec | ||

| 1 | T01 | Dhora 10-DIA 23.5 gomba rinokwira | Kudhirowa pasi-paburi DIA 23.5 | 23.50 | 150 | 2033 | 0.15 | 305 | 10 | 15.0 | 29.52 | 20 | 5 | ||

| 2 | T04 | 10-DIA 23 Orifice Chamfering | DIA 30 musanganiswa reaming chamfering cutter | 30.00 | 150 | 1592 | 0.20 | 318 | 10 | 3.0 | 6.65 | 20 | 5 | ||

| 3 | T06 | 10-DIA 23.5 Back orifice chamfering | DIA 22 reverse chamfering cutter | 22.00 | 150 | 2171 | 0.20 | 434 | 10 | 3.0 | 4.14 | 40 | 5 | ||

| 4 | T08 | Milling Marking Nzvimbo | DIA 30 square shoulder milling | 30.00 | 80 | 849 | 0.15 | 127 | 1 | 90.0 | 42.39 | 4 | 5 | ||

| Tsanangudzo: | Nguva yekucheka: | 82 | Chepiri | Inguva yekurovera nekugadzirisa uye yekurodha uye kuvharika zvinhu: | 30 | Chepiri | |||||||||

| Nguva yekubatsira: | 104 | Chepiri | Yese machining man-maawa: | 233.00 | Chepiri | ||||||||||

Nhanganyaya kune Production Line

Kurongeka kweKugadzira Line

Nhanganyaya kune Production Line

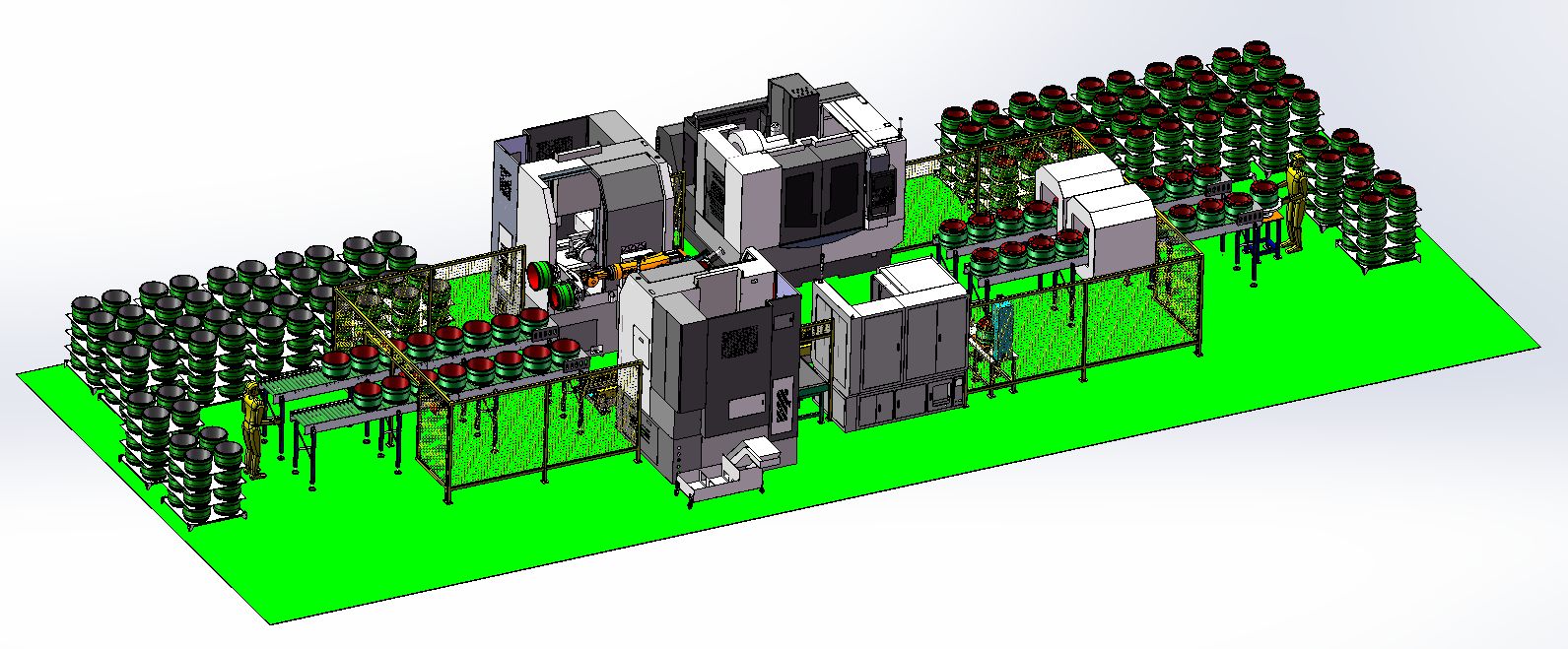

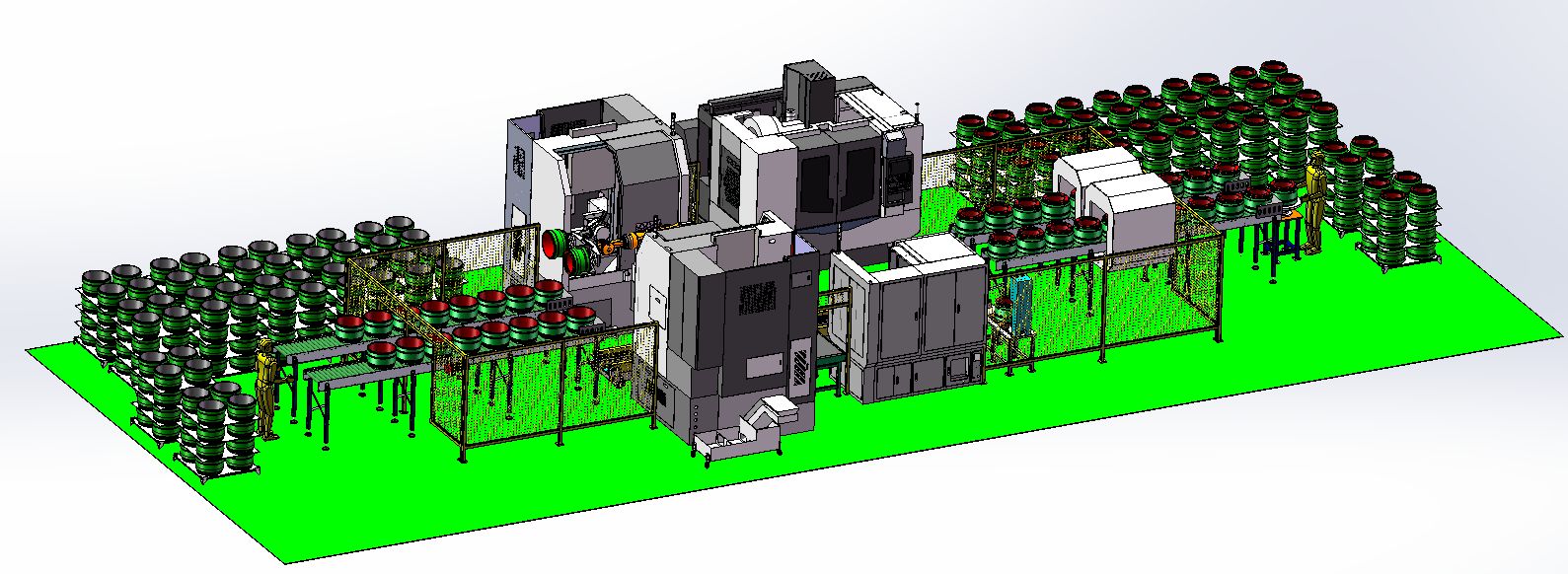

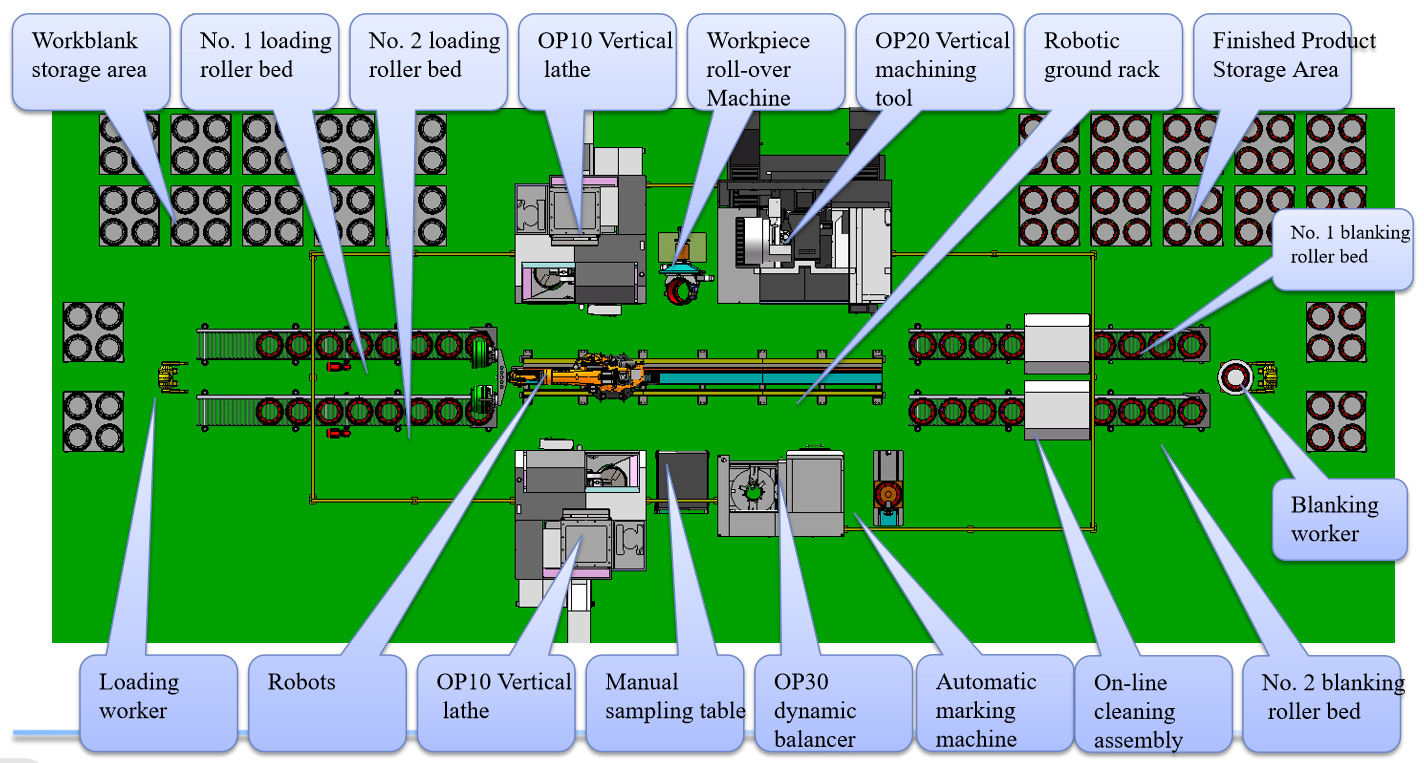

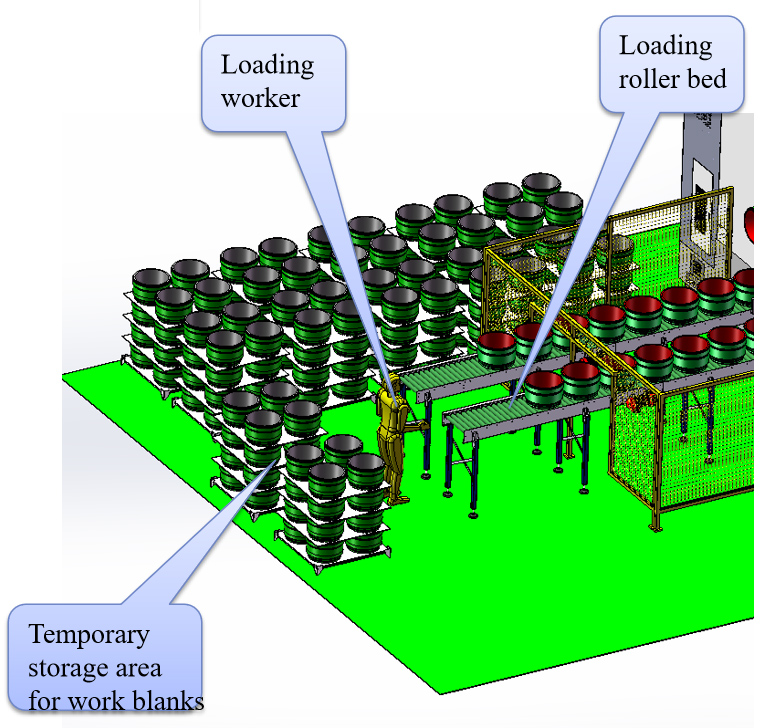

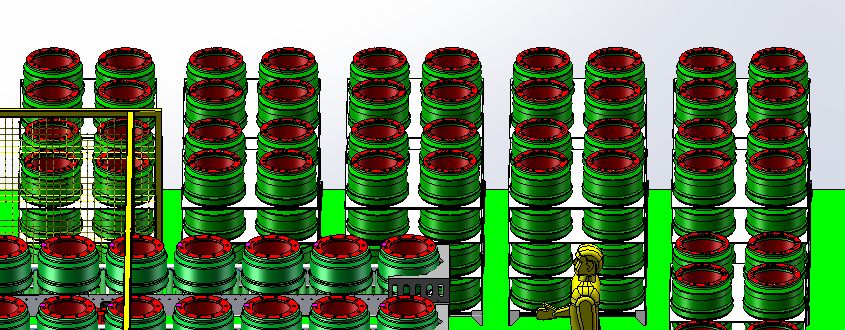

Mutsara wekugadzira une 1 yekurodha unit, 1 lathe machining unit uye 1 blanking unit. Marobhoti anotakura zvinhu pakati pezviteshi mukati mechikamu chimwe nechimwe. Forklifts inoisa mabhasikiti pamberi pekurodha uye blanking units; Mutsara wekugadzira unovhara nzvimbo ye: 22.5m×9m

Tsanangudzo yemutsetse wekugadzira

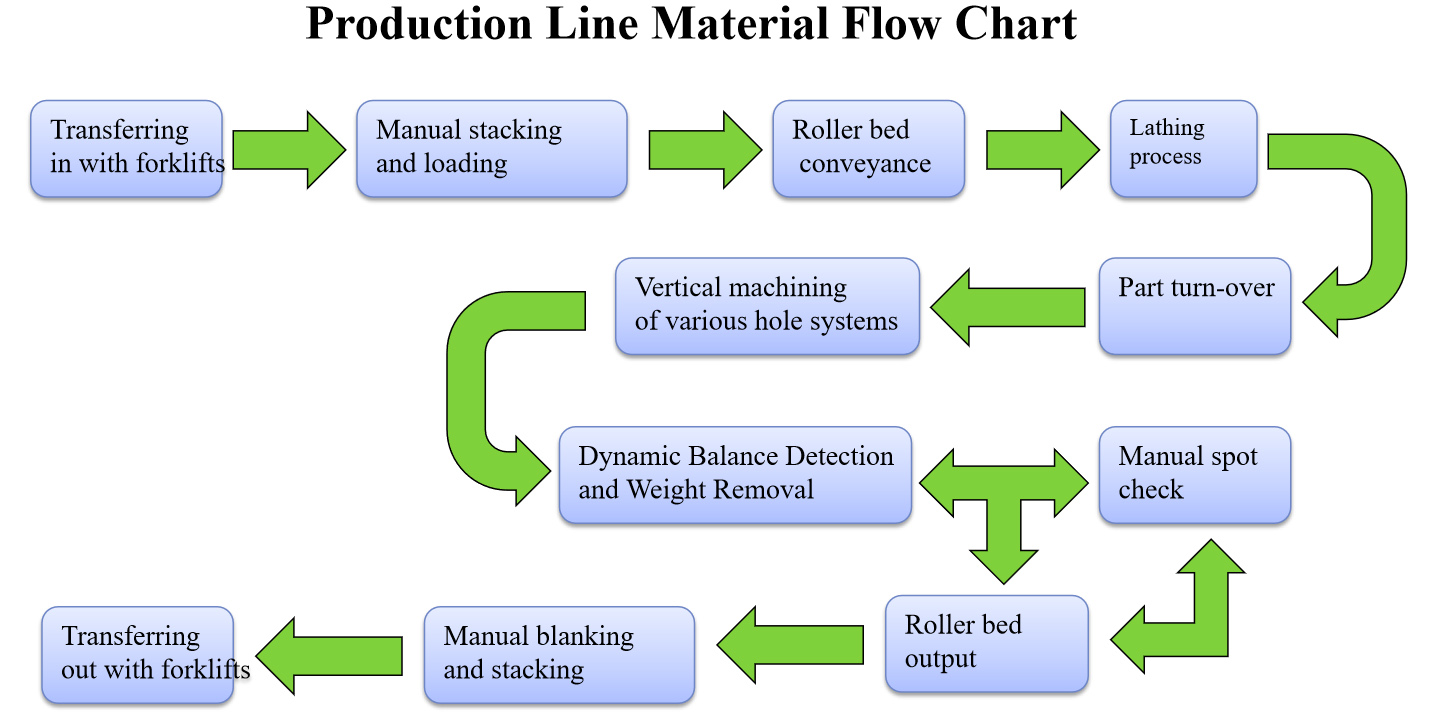

1. Zvivharo zvebasa zvinotakurwa kune zviteshi zvekurodha nemaforogo, zvakasimudzwa nemaoko kumubhedha webhedha, uye zvinotumirwa kune zviteshi zvekutakura kuburikidza nema rollers. Iko kurodha uye kurodha yemuchina wekuenzanisa mukuita lathe process, roll-over process uye yekudhirowa nekugayo inopedzwa nemarobhoti. Zvigadzirwa zvakapedzwa zvinotumirwa kune zviteshi zvisina blanking kuburikidza nemubhedha we roller, uye zvinotumirwa kunze neforklifts mushure mekusimudza nemaoko uye kurongedza;

2. Makuru-makuru emagetsi ekuratidzira masikirini achaiswa pamitsetse yekutakura zvinhu kuti ivandudze uye kuratidza ruzivo rwekubuda, zvigadzirwa zvisina kukwana uye kuchengetedzwa kwemazuva ekugadzira munguva chaiyo;

3. Mutsetse wekutumira uchapihwa chiedza chenyevero pachikwata chega chega, chinogona kuratidza ruzivo rwakadai sekugara, kushaya zvinhu uye zvinotyisa;

4. Automatic line inotora kushandiswa kweyuniti mode uye yakawanda-unit wiring mode, ine flexible marongerwo, inokodzera zvakasiyana-siyana zvekugadzirisa zvinodiwa nevatengi;

5. Gamuchira robhoti yakabatana yekurodha uye kuvhara, iyo ine kugadzikana kwepamusoro, kugadzirisa kuri nyore uye hupenyu hurefu hwebasa;

6. Kudiwa kuduku kwevashandi. Izvo zvinodikanwa zvevashandi zvezuva nezuva zvekuchinja kwega kwega kweiyi otomatiki mutsara ndezvizvi:

Forkliftman 1 ~ 2 vanhu (vane basa rekusimudza, forklifting uye kuendesa mabheji ebasa / zvigadzirwa zvakapedzwa)

Maintenance Injiniya 1 munhu (anotarisira maitiro ekugadzirisa-mafuta uye vateki vemvura, nezvimwewo)

7. Mutsara otomatiki une kuwedzera kwakasimba. Zvakadai seyakasanganiswa waya machining, workpiece traceability uye mamwe mabasa, ane yakaderera mutengo wekuwedzera;

Loading unit

1. Iyo yekurodha roller bed line inogona kuchengeta 12 × 16 = 192 zvidimbu; 2. Vhura nemaoko stack uye uisimudze kumubhedha wekutakura wekutakura uye utumire kuchiteshi chekutakura neroller conveyor; 3. Mushure mekuvhura murwi, tireyi isina chinhu ichasungirirwa uye kuiswa pamutsara usina kuvhara wematoyi asina chinhu, akaturikidzana muzvikamu 8, uye isina chinhu tirayi stacking ichabviswa nemaoko uye kuiswa munzvimbo yekuchengetedza;1. Iyo yekurodha roller bed line inogona kuchengeta 12 × 16 = 192 zvidimbu;

2. Vhura nemaoko stack uye uisimudze kumubhedha wekutakura wekutakura uye utumire kuchiteshi chekutakura neroller conveyor;

3. Mushure mokuzarura murwi, tereyi isina chinhu ichasungirirwa uye yakaiswa pamutsara usina kuvhara wetirasi dzisina chinhu, kuiswa muzvikamu zve 8, uye iyo isina tsvina stacking ichabviswa nemaoko uye kuiswa munzvimbo yekuchengetedza;

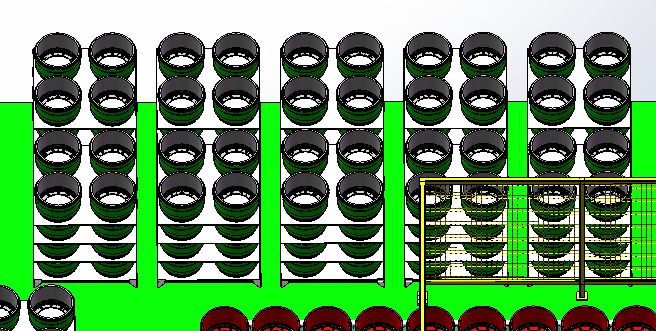

Nhanganyaya yekushanda blank stacks

1. Murwi mumwe wezvimedu gumi nematanhatu uye 4 akaturikidzana pamwe chete, aine mahwendefa ekuparadzanisa pakati pega ega;

2. Basa risina chinhu stack rinogona kuchengeta 160 zvidimbu;

3. Iyo pallet inokurudzirwa kugadzirirwa nemutengi. Zvinodiwa: (1) Kusimba kwakanaka uye flatness (2) kukwanisa kusungirirwa nerobhoti.

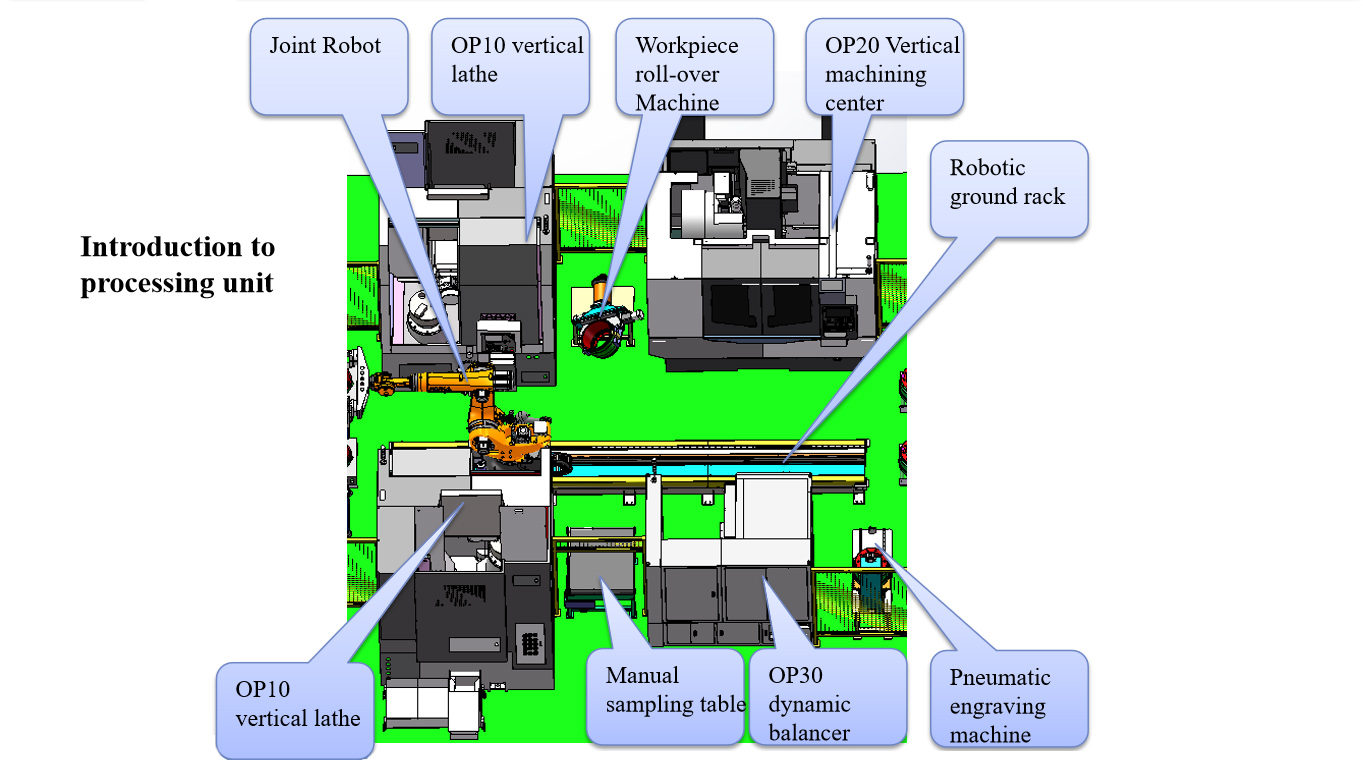

Nhanganyaya kune processing unit

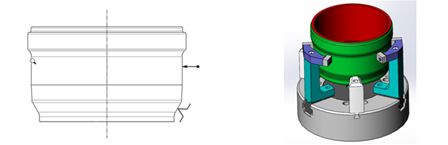

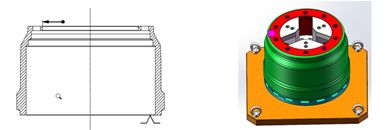

1. The lathing process ine maviri vertical lathes, No. 1 robhoti uye robhoti pasi rack, iyo inoita machining yekunze denderedzwa, mukati gomba nhanho pamusoro uye kuguma chiso chechikamu;

2. Roll-over station ine 1 rolling over machine, iyo inoita automatic rolling pamusoro pezvikamu;

3. Kuchera uye kugadzirwa kwekugadzira kunosanganisira 1 vertical machining centre uye imwe No.

4. Iyo dhizaini yekuenzanisa uye yekubvisa uremu inoumbwa neiyo vertical dynamic balancer, iyo inoita iyo dynamic balancing yekuona uye kubvisa huremu hwezvikamu;

5. Chiteshi chekutarisa chebhuku chine bhandi rekutakura, iro rinotakura kutakura kwenzvimbo yakatariswa zvikamu uye rinoshandiswa senzvimbo yekuongorora;

6. Nzvimbo yekushanda yemuchina wepneumatic engraving inoita basa rekunyora nekumaka zvigadzirwa zvose;

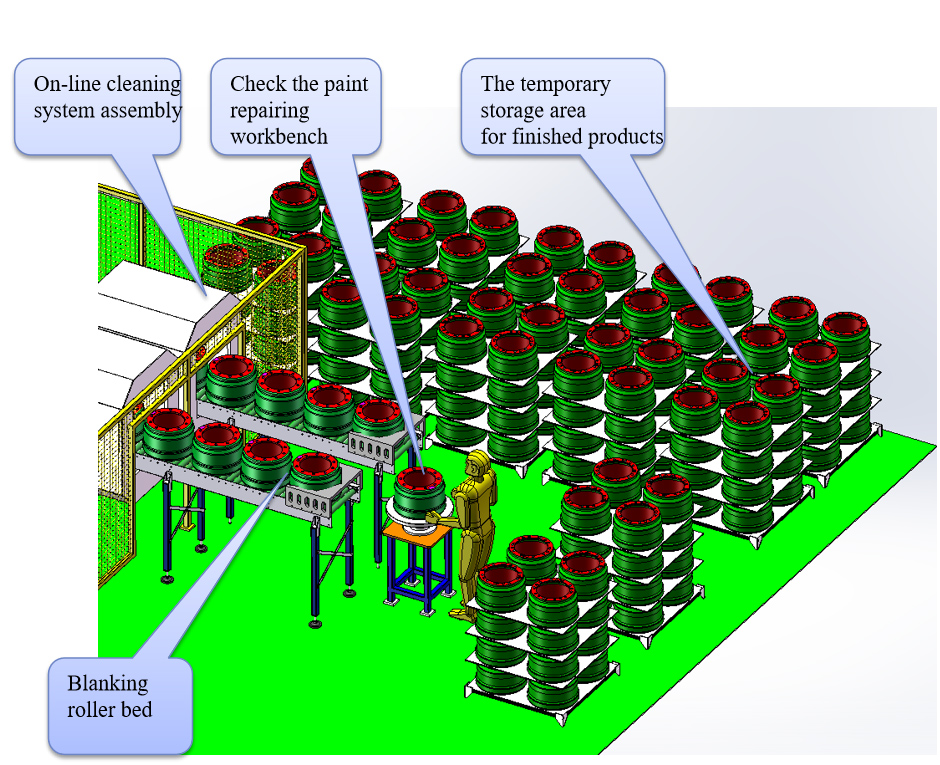

Nhanganyaya yeiyo blanking unit

1. Iyo yekurodha roller bed line inogona kuchengeta 12 × 16 = 192 zvidimbu;

2. Matireyi nemapureti ekuparadzanisa pachiteshi chekutakura zvinotakurwa kuenda kunzvimbo isina chinhu nemaforogo;

3. Zvigadzirwa zvakapedzwa zvinotakurwa kuchiteshi chisina blanking neroller conveyor, uye zvinosimudzwa uye zvakarongedzerwa nemaoko uye zvinotamiswa nemaforklift;

Nhanganyaya yekupedzisa chigadzirwa stacking

1. Murwi mumwe wezvimedu gumi nematanhatu uye 4 akaturikidzana pamwe chete, aine mahwendefa ekuparadzanisa pakati pega ega;

2.192 zvidimbu zvinogona kuchengetwa mudura rezvigadzirwa zvakapedzwa;

3. Iyo pallet inokurudzirwa kugadzirirwa nemutengi. Zvinodiwa: (1) Kusimba kwakanaka uye flatness (2) kukwanisa kusungirirwa nerobhoti.

Nhanganyaya yezvikamu zvikuru zvinoshanda zvemutsara wekugadzira

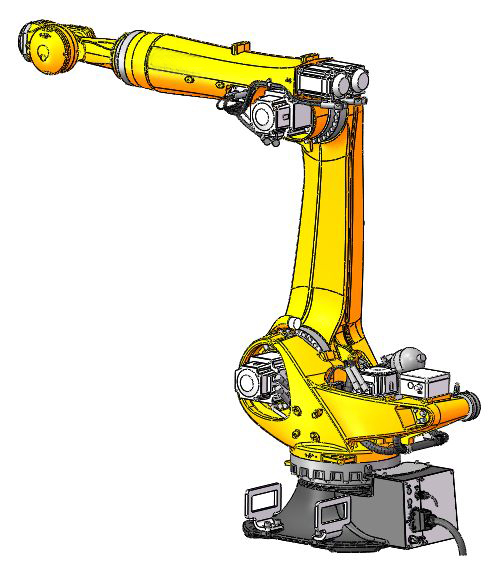

Nhanganyaya kuMachining uye Dynamic Balancing Weight Removal Unit Robot

Chenxuan robhoti: SDCX-RB08A3-1700

| Basic data | |

| Type | SDCX-RB08A3-1700 |

| Nhamba yemasanhu | 6 |

| Maximum coverage | 3100mm |

| Pose repeatability (ISO 9283) | ± 0.05mm |

| Kurema | 1134kg |

| Kudzivirirwa kupatsanurwa kwerobhoti | Chiyero chekudzivirira, IP65 / IP67in-line wrist(IEC 60529) |

| Mounting chinzvimbo | Sirin'i, kona inotenderwa yekurerekera ≤ 0º |

| Kupera kwepamusoro, pendi | Base furemu: dema (RAL 9005) |

| Ambient tembiricha | |

| Operation | 283 K kusvika 328 K (0 °C kusvika +55 °C) |

| Kuchengeta uye chekufambisa | 233 K kusvika 333 K (-40 °C kusvika +60 °C) |

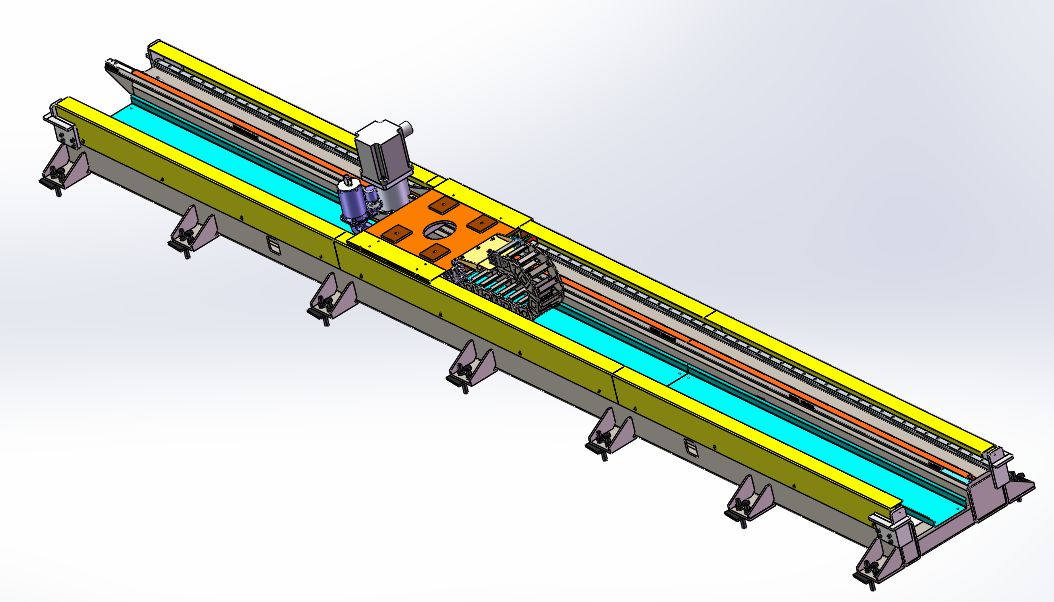

Nhanganyaya yeRobot Travel Axis

Chimiro chacho chinoumbwa nerobhoti rakabatana, servo motor drive uye pinion uye rack drive, kuitira kuti robhoti iite rectilinear kufamba nekudzoka. Iyo inoziva basa rerobhoti rimwe rinoshandisa akawanda maturusi emuchina uye inobata workpiece pazviteshi zvakati wandei uye inogona kuwedzera kuvharika kwekushanda kwemarobhoti akabatana;

Kufamba track inoshandisa base yakashomerwa nemapombi esimbi uye inofambiswa ne servo mota, pinion uye rack drive, kuwedzera kuvharika kwekushanda kwerobhoti yakabatana uye nekunatsiridza mwero wekushandiswa kwerobhoti;

Nzira yekufambisa inoiswa pasi;

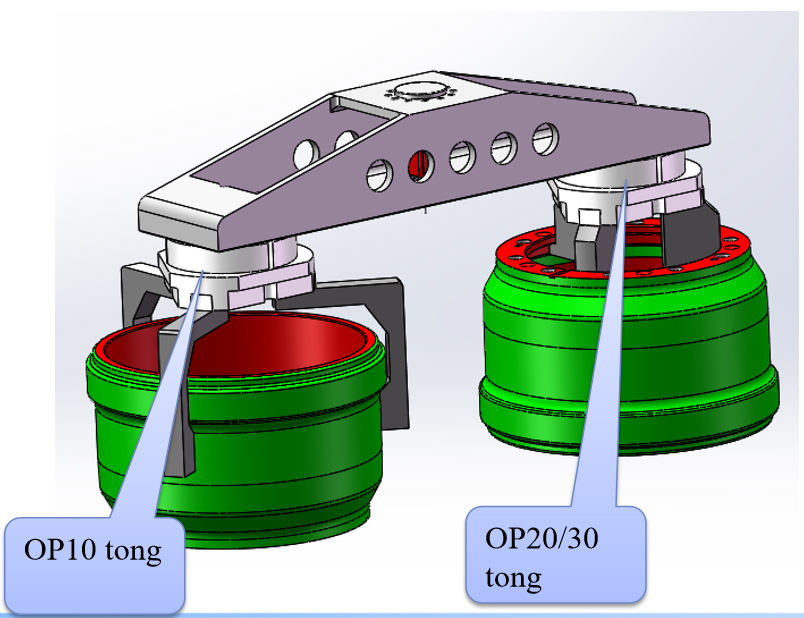

Kuunzwa kwematoni ekurodha uye asina chinhu marobhoti

Tsanangudzo:

1. Sezvimiro zvechikamu ichi, tinotora matatu-claw yekunze wave surface;

2. Iyo dhizaini inoshongedzerwa neiyo nzvimbo yekuona sensor uye yekumanikidza sensor kuti ione kana iyo clamping mamiriro uye kumanikidza kwezvikamu zvakajairika;

3. Iyo michina inoshongedzerwa nepressurizer, uye workpiece haizoputsike munguva pfupi kana kukanganisa kwesimba uye gasi kubviswa kwemhepo huru yedunhu;

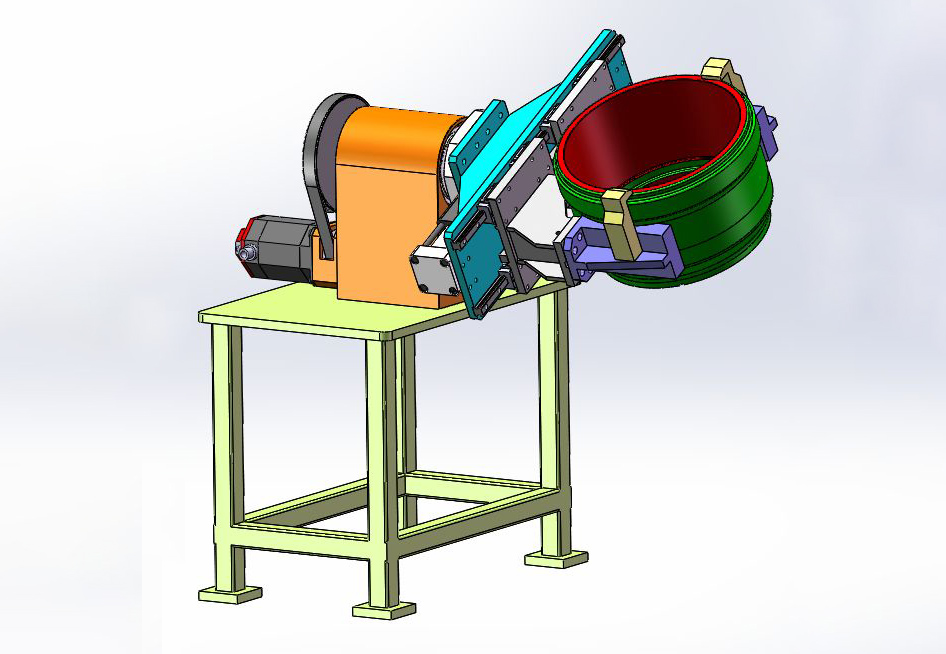

Kusuma otomatiki Roll-over Machine

Tsanangudzo:

Iyo meshini inoumbwa neyakagadziriswa furemu, yekutsigira base musangano uye pneumatic tong musangano. Iyo ine anti-yakasununguka uye anti-kudonha basa mushure mekucheka kwemhepo, uye inokwanisa kuona 180 ° roll pamusoro pemutsara workpieces;

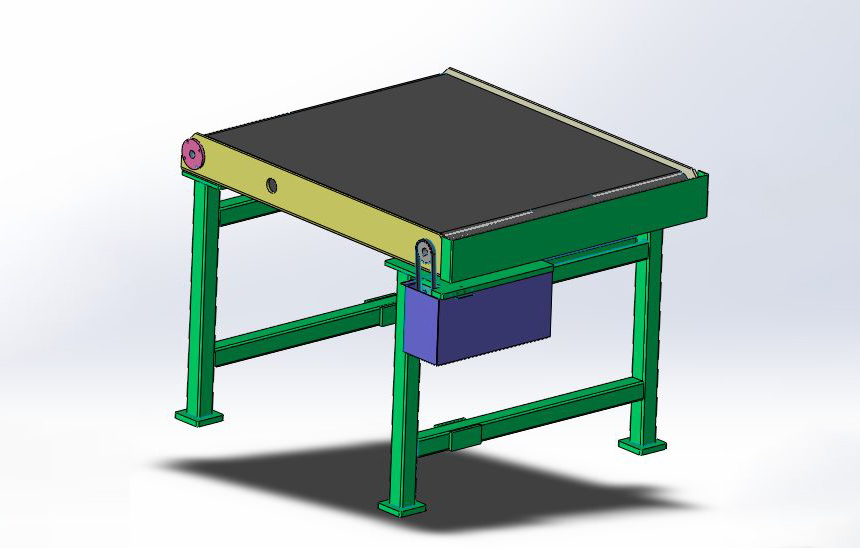

Nhanganyaya kune manual spot cheki bhenji

Tsanangudzo:

1. Seta manyorerwo akasiyana-siyana ekuenzanisa sampling frequency yezvikamu zvakasiyana zvekugadzira, izvo zvinogona kunyatso tarisa kushanda kweyero yepamhepo;

2. Mirayiridzo Yekushandisa: Iyo manipulator ichaisa iyo workpiece kunzvimbo yakagadziriswa panzvimbo yekutarisa bhenji maererano nefrequency set manually, uye nekukurumidza nechiedza chitsvuku. Muongorori achadzvanya bhatani kuti atakure workpiece kunzvimbo yakachengeteka kunze kwekuchengetedzwa, tora workpiece yekuyera uye uidzorere kumubhedha we roller mushure mekuyera;

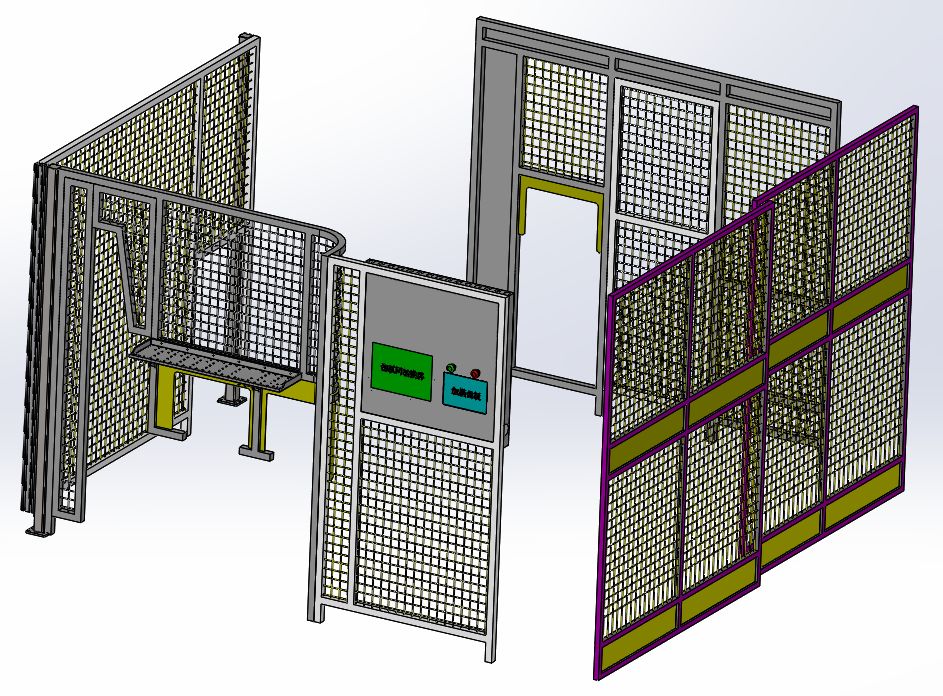

Zviviriro zvinodzivirira

Iyo inoumbwa neakareruka aluminium mbiri (40 × 40) + mesh (50 × 50), uye iyo yekubata skrini uye yekumisa bhatani bhatani rinogona kubatanidzwa pane zvinodzivirira, kubatanidza kuchengetedza uye aesthetics.

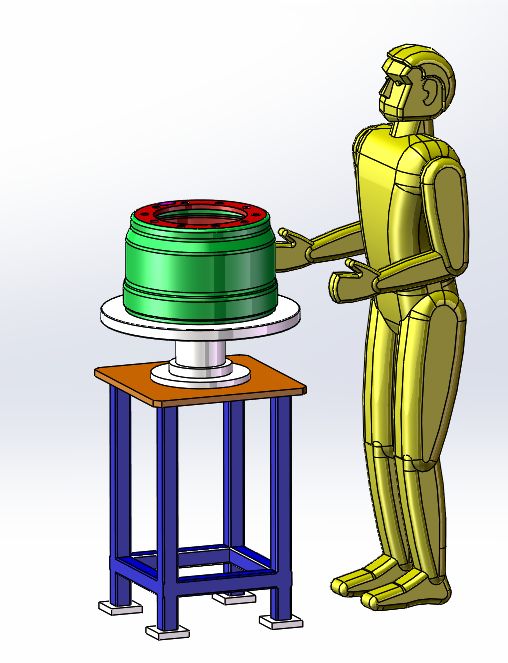

Nhanganyaya kuInspection Station yekugadzirisa pendi

Tsanangudzo:

Iyo michina inoumbwa neyakagadzika furemu uye turntable. Vashandi vanosimudza zvigadzirwa zvakapedzwa kune turntable, shandura turntable, tarisa kana pane zviputi, zvikwepa uye zvimwe zviitiko, uye kugadzirisa panguva yakakodzera kukanganisa kwebumping uye pendi pendi;