Project Zvinodiwa

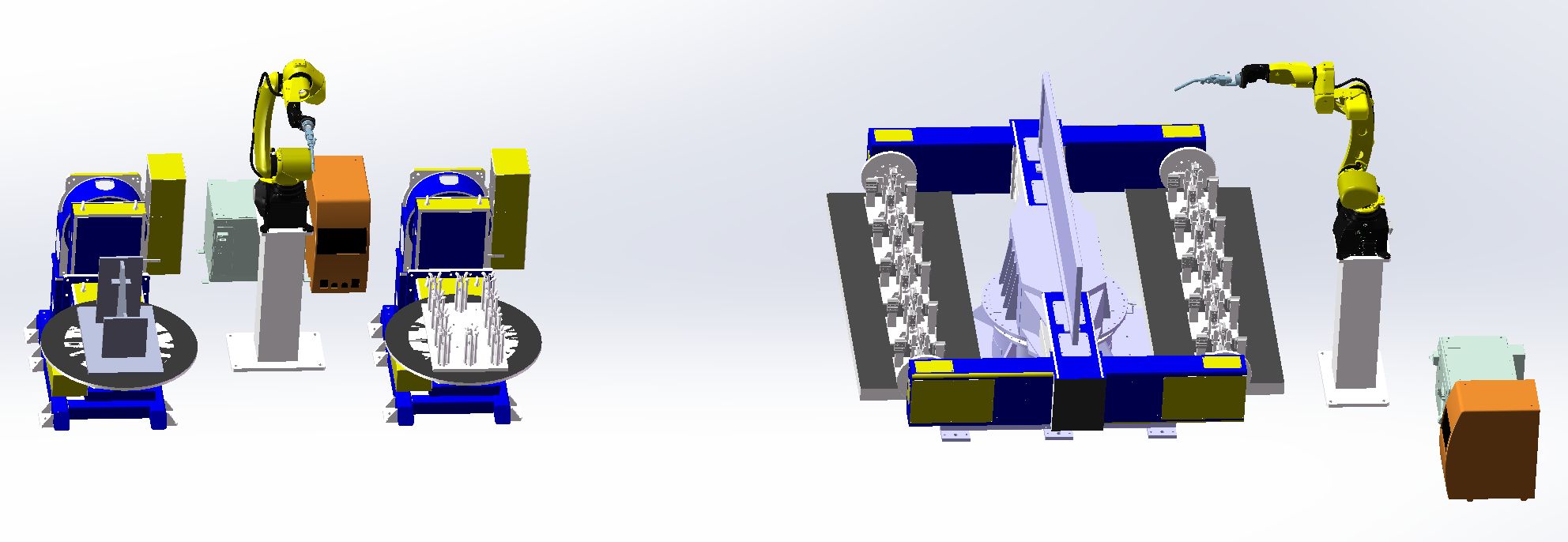

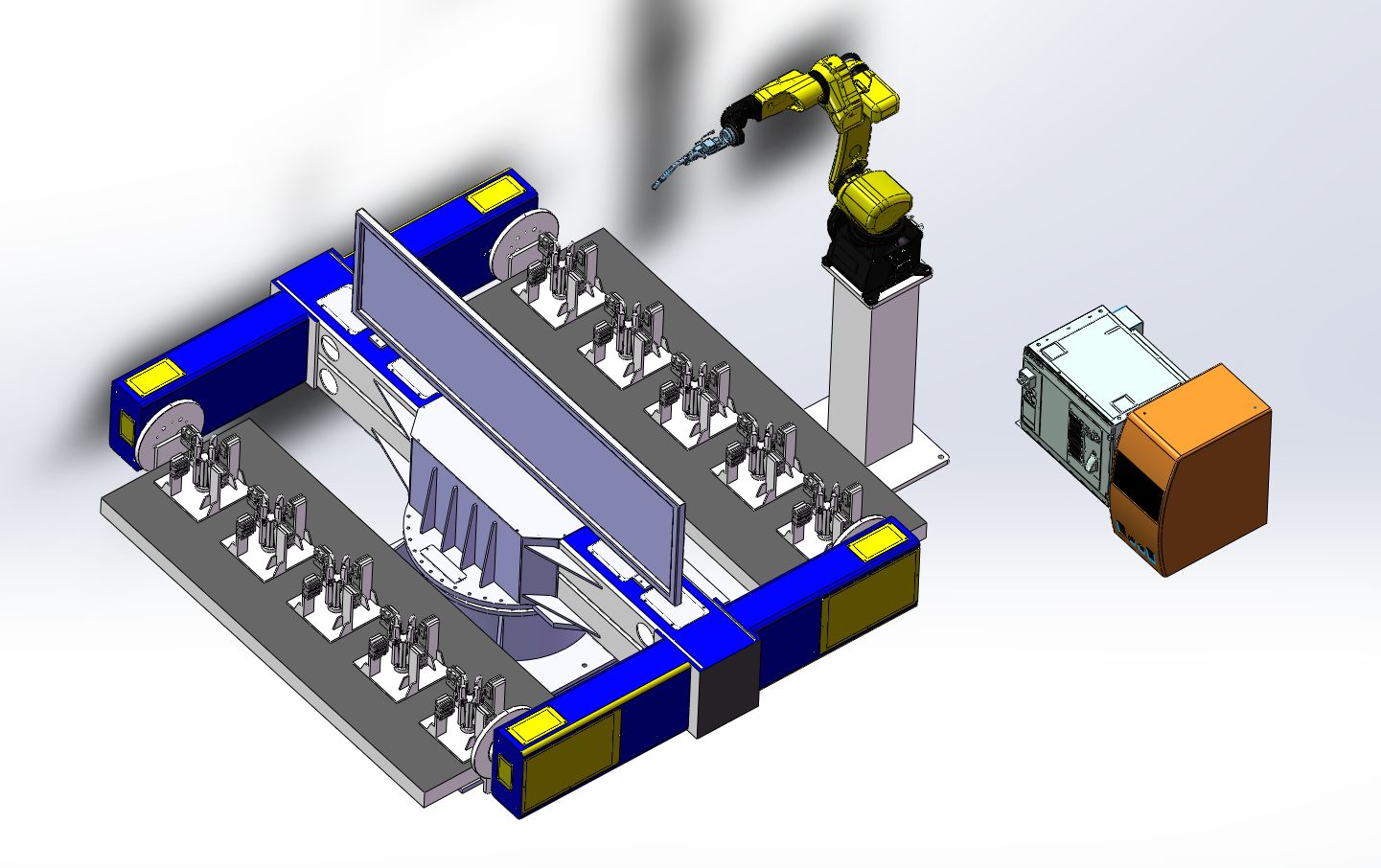

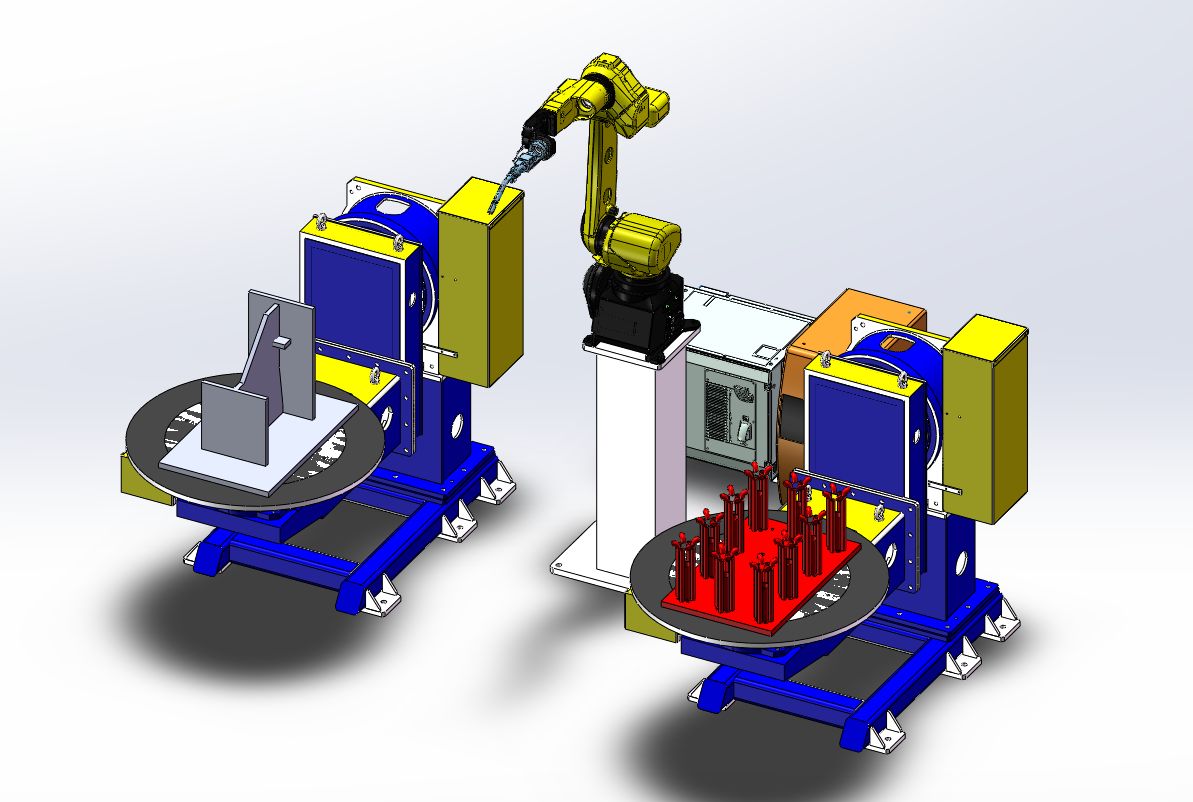

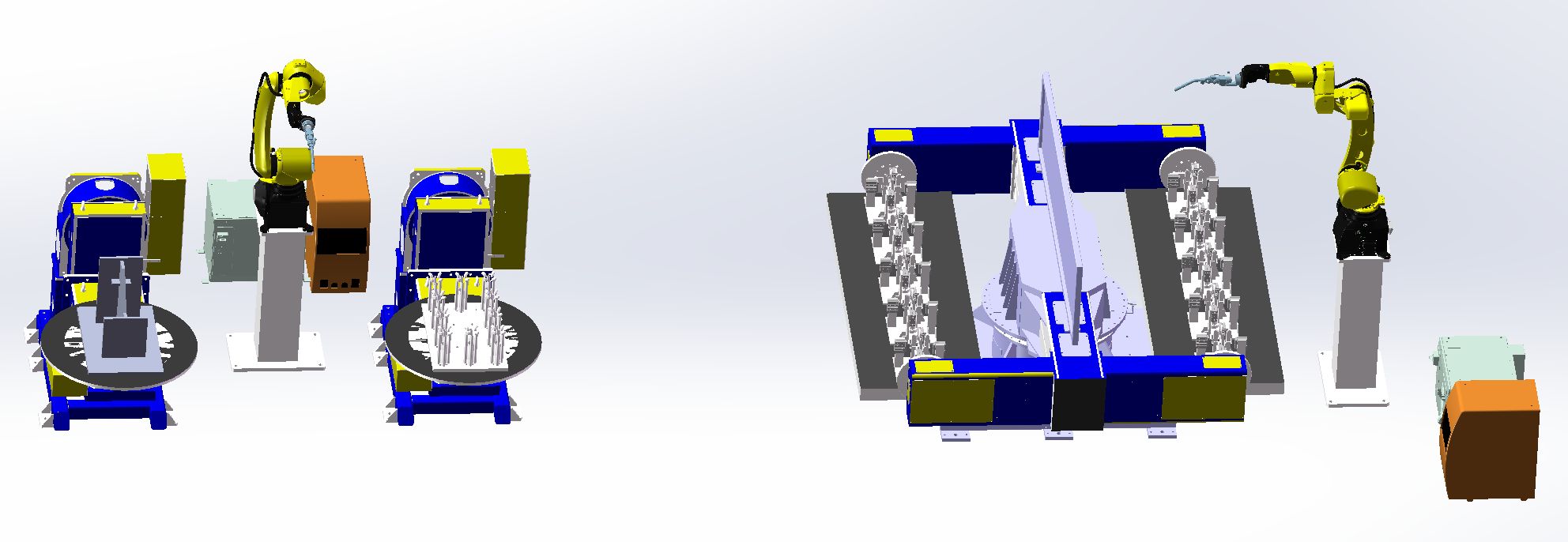

Yakazara Layout&3D Model

Ongorora: Iyo dhizaini yedhizaini inongoshandiswa kuenzanisira dhizaini uye haimiriri chimiro chemidziyo. Iyo chaiyo saizi ichatemwa zvinoenderana nemamiriro esaiti yemutengi.

Workpiece yemuviri kudhirowa & 3D modhi

Workpiece yemuviri kudhirowa & 3D modhi

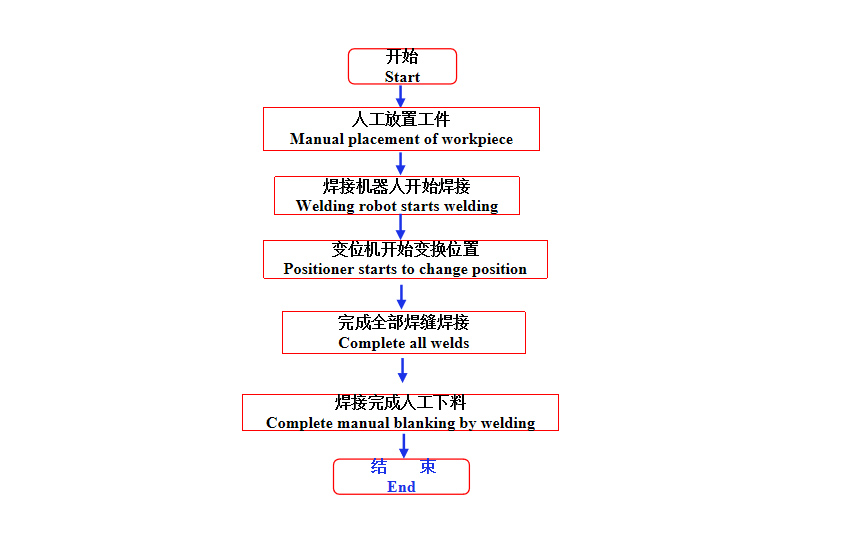

Workflow

Mamiriro ekushanda kweworkstation

(1) Pamaoko isa workpiece mune chinzvimbo uye gadzirisa zvinoenderana nezvinodiwa.

(2) Mushure mekunge zvishandiso zvese zvabatidzwa uye pasina alarm inoratidzwa, gadzirira kuisirwa.

(3) Robhoti inomira panzvimbo yebasa, uye chirongwa chekumhanya cherobhoti ndiyo inoenderana chirongwa chekugadzira.

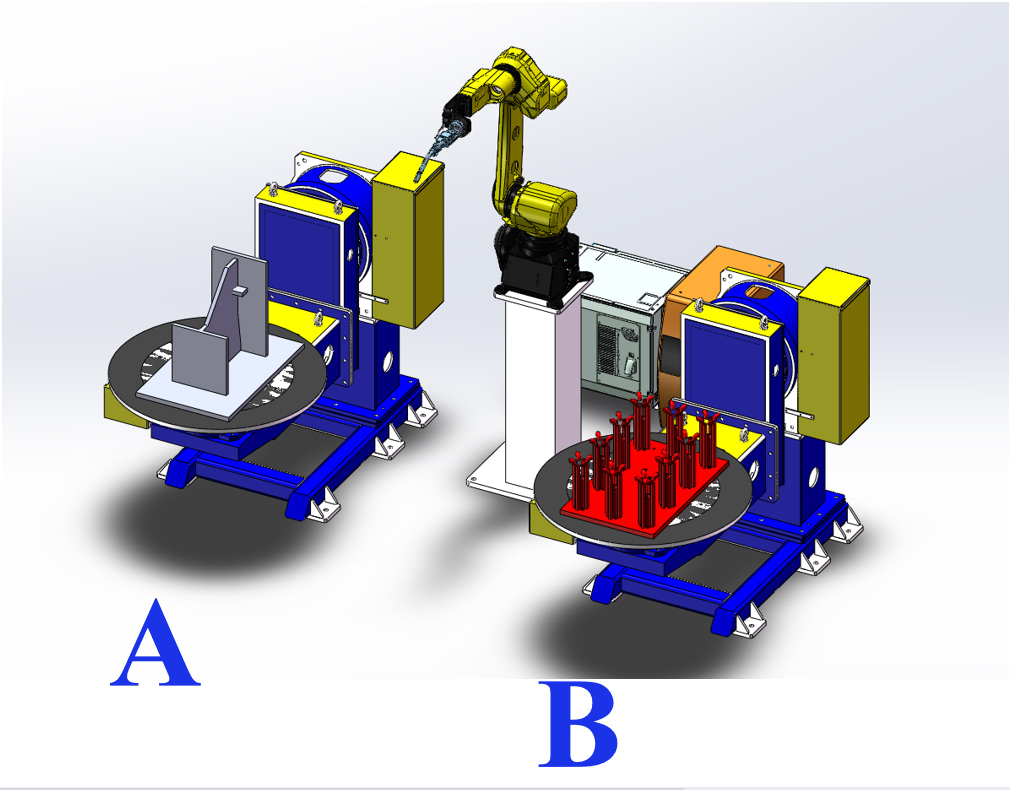

Welding process ye sleeve subassembly

1. Isa nemaoko seti shanu dzezvikamu zvemaoko padivi A.

2. Dzokera kunzvimbo yekuchengetedza nemaoko uye tanga bhatani clamp cylinder kuti usimbise workpiece.

3. Positioner inotenderera kusvika robhoti riri padivi peB ratanga welding.

4. Pamaoko tora pasi workpieces welded padivi A, uye ipapo mashanu seti dzezvigubhu zvikamu.

5. Kokorodza kushanda kwezvibatanidza zviri pamusoro.

Nguva yewelding yeseti yega yega yemaoko ndeye 3min (kusanganisira yekuisa nguva), uye nguva yewelding yemaseti gumi ndeye 30min.

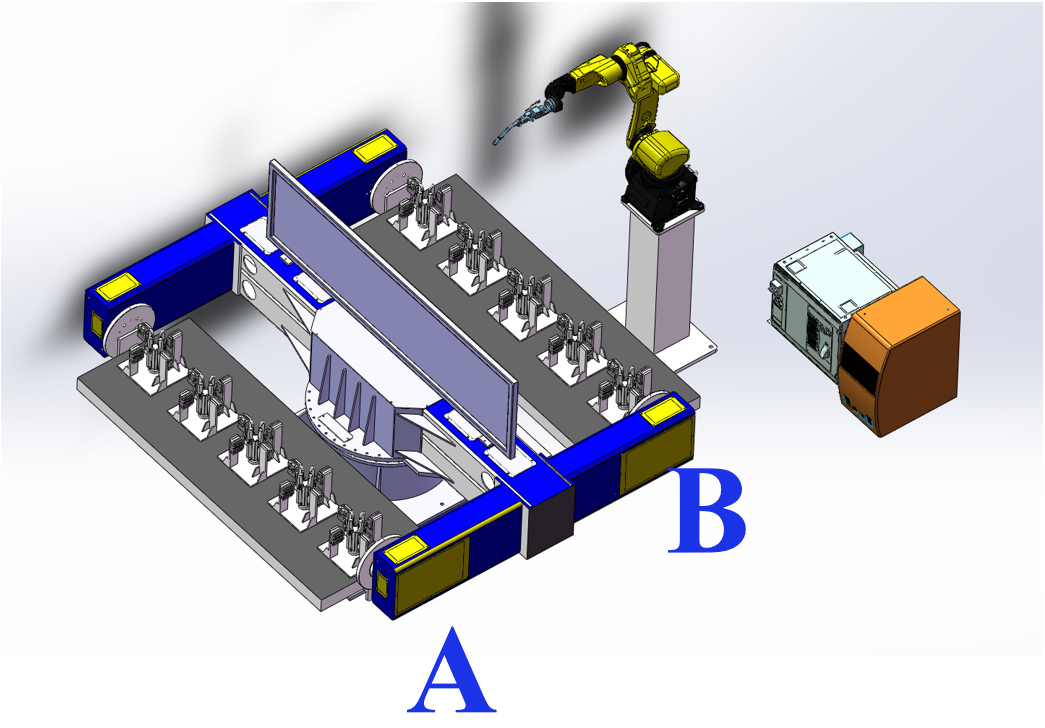

Welding process ye embedded plate assembly + sleeve assembly

1. Isai nemaoko ndiro yakadzikwa nechekare pane L-type positioner padivi A.

2. Tanga bhatani robhoti welding embedded plate assembly (15min / set). 3.

3. Isai nemaoko zvikamu zvisina kusimba zvegungano remaoko pane L-mhando yekumisikidza padivi B.

4. Robhoti rinoramba richiita weld the sleeve assembly after welding the embedded plate assembly(sleeve welding for 10min+manual installation yeworkpiece uye robhoti spot welding for 5min)

5. Bvisa gungano rakaiswa ndiro nemaoko.

6. Manual welding ye embedded plate assembly (kubvisa-spot welding-loading mukati me15min)

7. Isai nemaoko ndiro yakadzikwa nechekare pane L-type positioner padivi A.

8. Bvisa musangano we welded sleeve uye uise zvikamu zvakasara

9. Kokorodza kushanda kwezvibatanidza zviri pamusoro.

Welding yekupedzisa nguva yeakamisikidzwa ndiro ndeye 15min + welding yekupedzisa nguva yemusangano we sleeve ndeye 15min.

Nguva yose 30min

Nhanganyaya yeTong Changing Device

Nguva yewelding yerobhoti pane yataurwa pamusoro apa ndiyo yakanyanya kukwana pasina kumira. Zvinoenderana nemaawa masere pazuva uye vaviri vanoshanda, kubuda kwemagungano maviri kunosvika makumi matatu nemaviri seti pazuva.

Kuwedzera kuburitsa:

Robhoti rimwe rinowedzerwa kune matatu-axis positioner pasleeve subassembly station uye rinoshandurwa kuita kaviri muchina welding. Panguva imwecheteyo, iyo yakamisikidzwa ndiro yekuungana + sleeve yekusangana chiteshi inodawo kuwedzera maviri seti e-L-mhando positioner uye imwe seti yerobhoti. Pazuva remaawa masere uye matatu evashandisi, kubuda kwemagungano maviri kunosvika makumi matanhatu nemana pazuva.

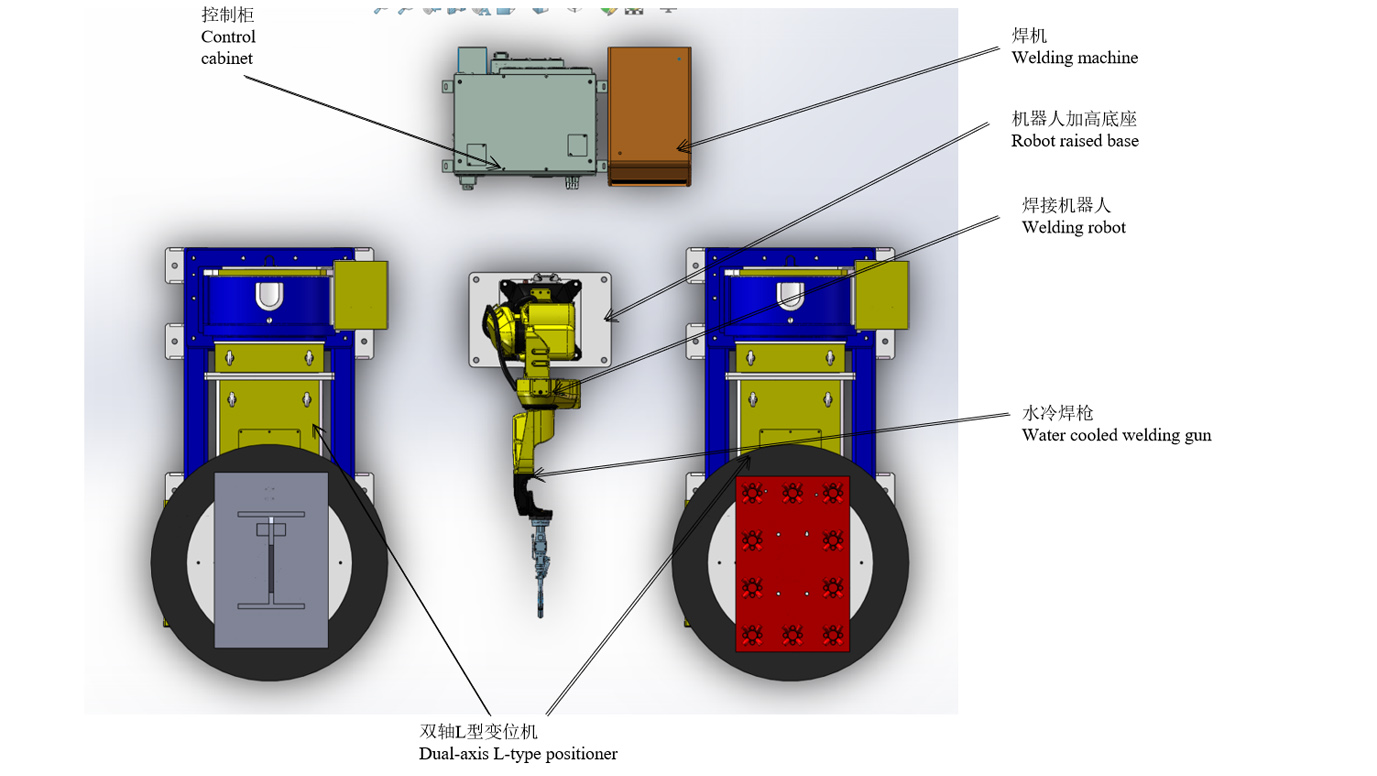

Equipment List

| Item | S/N | Zita | Qty. | ZVAKARERA |

| Robhoti | 1 | RH06A3-1490 | 2 seti | Yakapihwa naChen Xuan |

| 2 | Robot control cabinet | 2 seti | ||

| 3 | Robhoti yakasimudza base | 2 seti | ||

| 4 | Mvura yakatonhodzwa welding pfuti | 2 seti | ||

| Peripheral equipment | 5 | Welding Power Source MAG-500 | 2 seti | Yakapihwa naChen Xuan |

| 6 | Dual-axis L-mhando chinzvimbo | 2 seti | ||

| 7 | Three-axis horizontal rotary positioner | 1 set | Yakapihwa naChen Xuan | |

| 8 | Fixture | 1 set | ||

| 9 | Pfuti Cleaner | Set | Optional | |

| 10 | Kubvisa guruva midziyo | 2 seti | ||

| 11 | Safety fence | 2 seti | ||

| Related Service | 12 | Kuiswa uye kutumwa | 1 chinhu | |

| 13 | Packaging uye Kutakura | 1 chinhu | ||

| 14 | Kudzidziswa kwehunyanzvi | 1 chinhu |

Kutsanangurwa Kwehunyanzvi

Pfuti yewelding yakavakirwa mumvura-yakatonhorera

1) Pfuti yega yega yekubatira ichapfuura nemuyero we ternary kuti ive nechokwadi chekurongeka kwedimensional;

2) Chikamu cheR chepfuti yewelding inogadzirwa nenzira yakanyorova yekukanda wax, iyo isingazokanganisika nekuda kwekupisa kwakanyanya kunogadzirwa newelding;

3) Kunyange kana pfuti yemoto ichipindirana neworkpiece uye fixture panguva yekushanda, pfuti yekuputika haigoni kukotama uye hapana kugadziriswa zvakare kunodiwa;

4) Kuvandudza rectifier mhedzisiro yekudzivirira gasi;

5) Kurongeka kwebhari imwe chete iri mukati me0.05;

6) Mufananidzo wacho ndewekutarisa chete, uye uri pasi pesarudzo yekupedzisira.

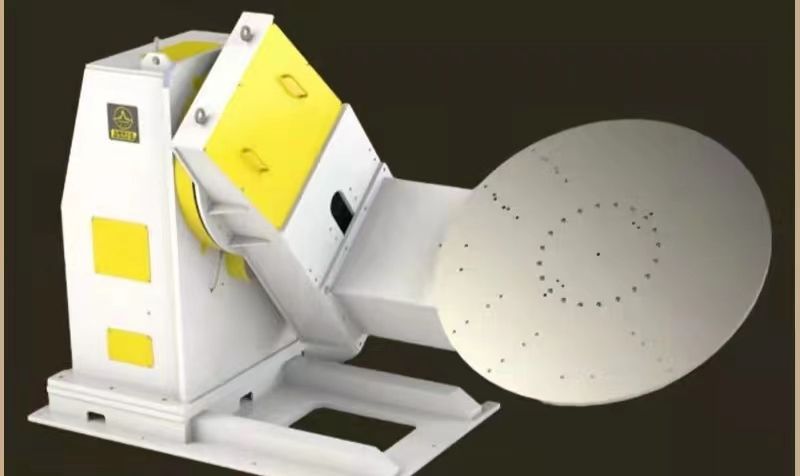

Dual-axis L-mhando chinzvimbo

Positioner yakakosha welding yekubatsira midziyo, iyo inokodzera welding displacement yebasa rinotenderera, kuitira kuti uwane yakakodzera machining chinzvimbo uye welding kumhanya. Inogona kushandiswa ne manipulator uye welding muchina kuumba otomatiki welding centre, uye inogona zvakare kushandiswa kuchinjisa workpiece panguva yekushanda kwemanyorero. Variable inobuda ine inosiyana-frequency drive inogamuchirwa yebasa rekutenderera kutenderera, ine yakanyanya kurongeka yekumhanyisa mutemo. Remote control bhokisi inogona kuona kure kure kushanda kwebhenji rebasa, uye zvakare inogona kubatanidzwa ne manipulator uye welding muchina kudzora system kuti uone yakabatana mashandiro. Iyo welding positioner inowanzo umbwa neyekutenderera michina uye yekuchinja nzira yebhenji rebasa. Iyo workpiece yakagadziriswa pabhenji yebasa inogona kusvika kune inodiwa welding uye kona yegungano kuburikidza nekusimudza, kutendeuka uye kutenderera kwebhenji rekushanda. Iyo bhenji yebasa inotenderera kuita inosiyana frequency nhanho yekumhanyisa kudzora, iyo inogona kuwana inogutsa welding kumhanya.

Mifananidzo ndeyekutarisa chete, uye inoenderana nekugadzirwa kwekupedzisira.

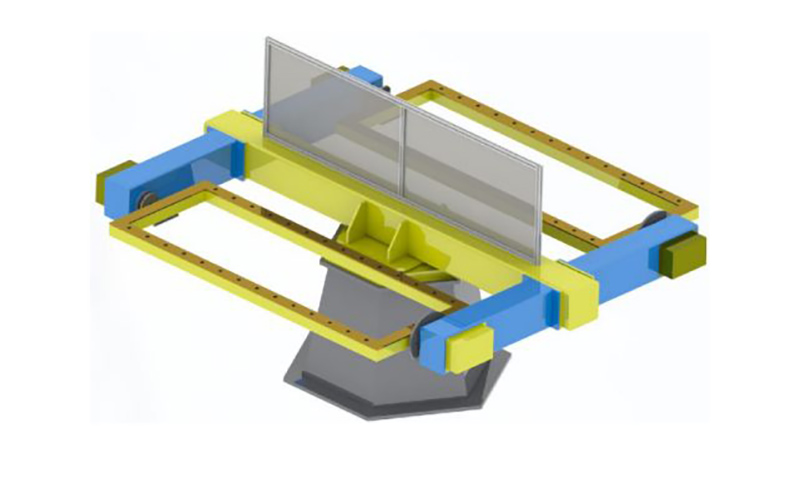

Three-axis horizontal rotary positioner

1) Three-axis horizontal rotary positioner inonyanya kuumbwa neyakagadzika chigadziko, rotary spindle bhokisi uye muswe bhokisi, welding furemu, servo mota uye chaiyo inoderedza, conductive mechanism, chivharo chekudzivirira uye magetsi ekudzora system, nezvimwe.

2) Nekugadzirisa akasiyana servo motors, iyo positioner inogona kushandiswa kure kuburikidza nerobhoti murayiridzi kana kunze kwebhokisi rekushanda;

3) Iyo inodiwa welding uye kona yegungano inowanikwa nekushandura workpiece yakagadzika pane workbench;

4) Kutenderera kwebhenji rekushanda kunodzorwa ne servo mota, iyo inogona kuwana yakanakira welding kumhanya;

5) Mifananidzo ndeyekutarisa chete, uye iri pasi pekupedzisira dhizaini;

Welding simba rekupa

Iyo inokodzera splicing, lapping, kona yejoint, chubhu plate butt joint, intersection line yekubatanidza uye mamwe mafomu akabatana, uye inogona kuona ese chinzvimbo welding.

Kuchengeteka uye kuvimbika

Muchina wewelding uye waya feeder ine yakawandisa-ikozvino, yakawandisa-voltage uye pamusoro-tembiricha yekudzivirira. Ivo vakapasa EMC uye magetsi ekuita bvunzo inodiwa nenyika standard GB/T 15579, uye vakapasa 3C certification kuona kuvimbika uye kuchengetedzeka mukushandiswa.

Kuchengetedza magetsi uye kuchengetedza kwezvakatipoteredza

Iyo nguva yekuona gasi, kumberi gasi rekupa nguva uye lag gasi rekupa nguva inogadziriswa kuti ive nechokwadi chekushandisa gasi zvine musoro. Kana iyo welding muchina ichiiswa simba, kana ikasapinda mune welding mamiriro mukati me2 maminetsi (nguva inogadziriswa), inongoerekana yapinda munzvimbo yekurara. Dzima fan uye kuderedza kushandiswa kwesimba.

Mufananidzo wacho ndewekutarisa chete, uye unoenderana nesarudzo yekupedzisira.

Welding simba rekupa

Pfuti yekuchenesa uye silicone mafuta yekupfapfaidza mudziyo uye waya yekucheka mudziyo

1) Silicone mafuta yekupfapfaidza mudziyo weiyo pfuti yekuchenesa chiteshi inotora kaviri nozzle yekupfapfaidza, kuitira kuti mafuta esilicone asvike mukati memukati wewelding torch nozzle zvirinani uye ive nechokwadi chekuti welding slag haizonamatira kumuromo.

2) Pfuti yekuchenesa uye silicone mafuta ekupfapfaidza zvishandiso zvakagadzirirwa panzvimbo imwechete, uye robhoti inogona kupedzisa maitiro e-silicone kupfapfaidza mafuta uye kuchenesa pfuti nechiito chimwe chete.

3) Panyaya yekudzora, iyo pfuti yekuchenesa uye silicone mafuta yekupfapfaidza mudziyo inongoda chiratidzo chekutanga, uye inogona kutangwa zvinoenderana neyakatsanangurwa chiitiko kutevedzana.

4) Chigadzirwa chekucheka kwewaya chinotora chimiro chekuzvigadzira chepfuti yewelding, iyo inobvisa kukosha kwekushandisa solenoid mavharuvhu kuidzora uye kurerutsa kurongeka kwemagetsi.

5) Chigadziro chekucheka kwewaya chinogona kuiswa zvakasiyana kana kuiswa papfuti yekuchenesa uye silicone mafuta spraying device kuti iite chigadzirwa chakabatanidzwa, icho chisingaiti chete kuchengetedza nzvimbo yekuisa, asiwo inoita kuti kurongeka uye kutonga kwegasi nzira nyore.

6) Mufananidzo wacho ndewekutarisa chete, uye uri pasi pesarudzo yekupedzisira.

Security fence

1. Isa mafenzi ekudzivirira, magonhi ekuchengetedza kana gireti dzekuchengetedza, kiyi dzekuchengetedza uye zvimwe zvigadziriso, uye itisa inodiwa inovharira kudzivirira.

2. Gonhi rekuchengetedza richaiswa panzvimbo yakakodzera yefenzi yekudzivirira. Ese magonhi achave akashongedzerwa nekuchengetedza switch uye mabhatani, reset bhatani uye emergency stop bhatani.

3. Mukova wekuchengetedza wakavharwa nehurongwa kuburikidza nekuchengetedza lock (switch). Kana gonhi rekuchengetedza rakavhurwa zvisina kujairika, sisitimu inomira kushanda uye inopa alarm.

4. Matanho ekuchengetedza kuchengetedza anovimbisa kuchengetedzwa kwevashandi nemidziyo kuburikidza nehardware uye software.

5. Iyo fence yekuchengetedza inogona kupiwa nePati A pachayo. Zvinokurudzirwa kushandisa yepamusoro-mhando grid welding uye kubika yero yambiro pendi pamusoro.

Electrical Control System

1. Inosanganisira kutonga kwehurongwa uye kutaurirana kwechiratidzo pakati pemidziyo, kusanganisira masensa, tambo, slots, switch, nezvimwewo;

2. Iyo otomatiki unit yakagadzirwa neatatu-mavara alarm light. Panguva yekushanda kwemazuva ose, chiedza chemavara matatu chinoratidza girini; kana chikwata chikakundikana, chiedza chemavara matatu chicharatidza tsvuku tsvuku munguva;

3. Pane mabhatani ekumira echimbichimbi pane robhoti control cabinet uye bhokisi rekudzidzisa. Muchiitiko chekukurumidzira, bhatani rekumisa emergency rinogona kudzvanywa kuti uone kumira kwechimbichimbi kweiyo system uye kutumira chiratidzo chealarm panguva imwe chete;

4. Zvirongwa zvakasiyana-siyana zvekushandisa zvinogona kuumbwa kuburikidza nemudziyo wekudzidzisa, zvikumbiro zvakawanda zvinogona kuumbwa, izvo zvinogona kusangana nezvinodiwa zvekuvandudza chigadzirwa uye zvigadzirwa zvitsva;

5. Zvose zviratidzo zvekumira zvekukurumidzira zvehurongwa hwose hwekutonga uye kuchengetedzwa kwekuchengetedza zviratidzo pakati pekugadzirisa michina uye marobhoti zvakabatana nehurongwa hwekuchengetedza uye hunopindirana kuburikidza nehurongwa hwekutonga;

6. Iyo yekudzora sisitimu inoziva chiratidzo chekubatanidza pakati pemichina yekushandisa yakadai serobhoti, kurodha bhini, gripper uye machining zvishandiso.

7. Machine tool system inoda kuona masign exchange nerobhoti system.

Nzvimbo yekushanda (yakapihwa neBato A)

| Magetsi | Simba rekushandisa: matatu-chikamu mana-waya AC380V ± 10%, voltage fluctuation range ± 10%, frequency: 50Hz; Iyo magetsi eiyo robot control cabinet inodiwa kuve yakashongedzerwa nemhepo yakazvimirira switch; Robhoti yekudzora kabhineti inofanirwa kuve yakadzikwa nepasi pekudzivirira isingasviki 10Ω; Iyo nhambwe inoshanda pakati pemagetsi uye robhoti yemagetsi control cabinet iri mukati me5 metres. |

| Mhepo source | Mhepo yakamanikidzwa ichasefa kubvisa hunyoro uye tsvina, uye iyo inobuda mumhepo mushure mekupfuura nepakati petatu ichave 0.5 ~ 0.8Mpa; Iyo inobudirira kureba pakati pemhepo sosi uye robhoti muviri iri mukati me5 metres. |

| Foundation | Iyo yakajairwa simende pasi yemusangano weParty A ichashandiswa kurapwa, uye mabhesi ekuisa ega ega mudziyo achaiswa pasi nemabhaudhi ekuwedzera; Concrete simba: 210 kg / cm 2; Ukobvu hwekrete: yakakura kupfuura 150 mm; Foundation kusaenzana: isingasviki ± 3mm. |

| Environmental Conditions | Ambient tembiricha: 0 ~ 45°C; Hunyoro hunyoro: 20% ~ 75% RH (hapana condensation); Vibration acceleration: isingasviki 0.5G |

| Zvimwe | Dzivisa magasi anopisa uye anoparadza uye zvinwiwa, uye usasasa mafuta, mvura, guruva, nezvimwewo; Ramba kure nenzvimbo dzeruzha rwemagetsi. |